Castle Donington-based

LK Metrology has released the latest version of its 3-D inspection software, FOCUS 2025 R1, which now forms an integral part of the company’s metrology suite. Designed to complement LK’s range of portable measuring arms and coordinate measuring machines (CMMs), the software introduces a host of enhancements aimed at streamlining point-cloud inspection and enhancing user experience.

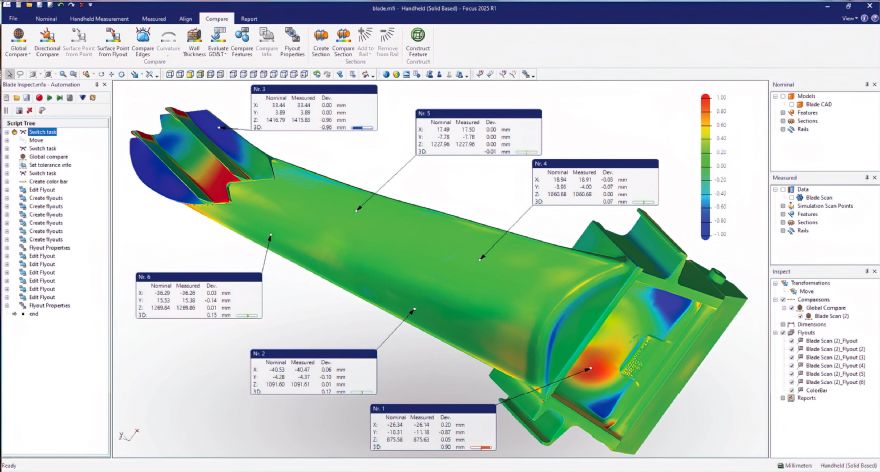

Branded in line with LK’s existing product portfolio, FOCUS 2025 R1 is engineered to work seamlessly with the company’s handheld H120 laser scanner and FREEDOM arms. The software’s graphical user interface has been refined to offer immediate familiarity, with a ribbon taskbar guiding users through each stage of the inspection process — from nominal part definition and feature extraction to GD&T analysis, alignment and reporting.

A notable addition is the NM API 5.0 R1 installer, which ensures optimal compatibility between the software and LK’s latest scanning hardware. The file menu has also undergone a modernisation, adopting a backstage interface that improves visibility of recent files and their locations.

Furthermore, FOCUS supports a wide array of CAD formats, including neutral standards such as STEP and IGES, as well as native formats like CATIA, Creo, NX, SolidWorks, ACIS, VDA-FS and Parasolid. This broad compatibility facilitates a smooth flow of data between design, manufacturing and quality control departments. The software’s tightly integrated data acquisition and intelligent processing capabilities allow for direct access to workflow customisation and automation, with results presented in clear graphical or tabular formats for easy interpretation and sharing.

Among the standout features is the ability to handle point clouds of virtually unlimited size, including those exceeding 100 million points. The proprietary FUSE algorithm automatically generates high-quality polygon meshes by intelligently leveraging scanner metadata. Advanced feature detection routines are capable of identifying and analysing a wide range of geometric elements, from simple holes and slots to more complex fir-tree and T-stud features.

Tactile probingThe software also supports tactile probing and includes a ‘leapfrog’ function for inspecting large components by repositioning the measuring device. Virtual assembly functionality enables digital builds using reference parts and CAD or point cloud data, eliminating the need for physical templates and fixtures.

Automation is a central theme in this release. FOCUS 2025 R1 incorporates macro-based recording of actions, allowing users to automate entire inspection workflows without requiring programming expertise. The software also includes specialised modules such as ‘Airfoil Inspection’, which calculates aerofoil profile measurements from cross-sections and generates dedicated reports.

The versatility of FOCUS 2025 R1 makes it suitable for a wide range of sectors. In aerospace and defence, it supports quality control of landing systems, engine blades and structural components, as well as MRO operations. Automotive applications include press and body inspection, benchmarking, aerodynamics, ergonomics and styling. The software also finds use in general manufacturing, heavy industry, power generation, healthcare and consumer goods.

Dave Robinson, LK’s marketing manager, said: “As industries continue to evolve towards smarter and more connected manufacturing, the role of digital inspection becomes ever more important. FOCUS 2025 R1 reflects not only this trend, but also our philosophy of continuous innovation.

“We have listened closely to our customers and invested in capabilities that simplify complex inspection, while ensuring compatibility with the latest scanning technologies. The result is a software release that is not only powerful but also intuitive, designed to help our users maximise their productivity.”