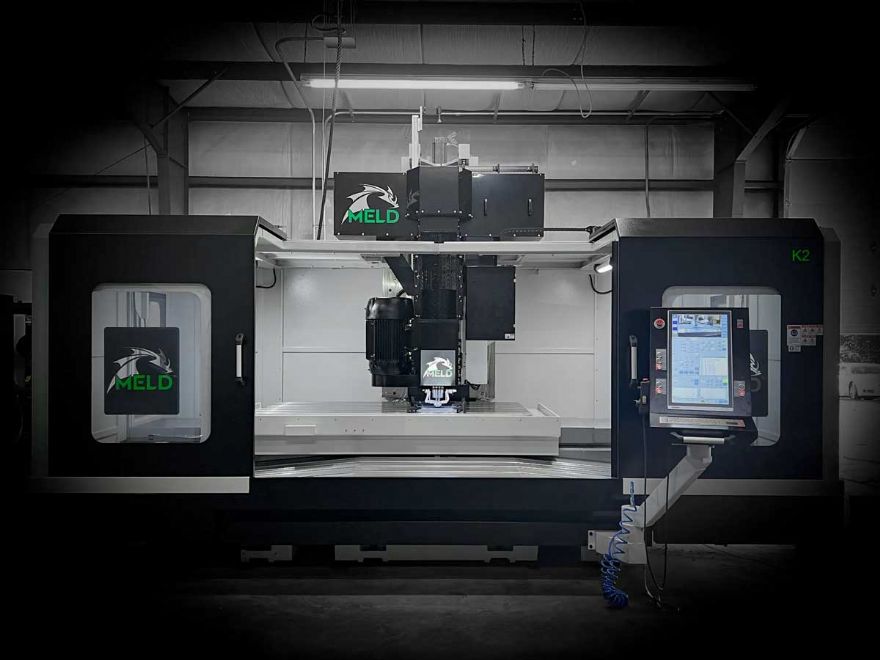

Photo: Meld MachinesMeld Manufacturing Corporation

Photo: Meld MachinesMeld Manufacturing Corporation has announced the launch of its DragonForge Series, a new line of machines engineered to transform the landscape of large-scale metal additive manufacturing (AM). The new machines are specifically designed to handle the deposition of aerospace alloys, including titanium and high-strength aluminum, for the production of large parts — while maintaining the forging-like quality that has become Meld’s hallmark.

Nanci Hardwick, Meld Machines’ CEO, said: “Years of research and development (R&D) have culminated in this new machine line, which brings together advanced hardware and software to address the demanding requirements of the aerospace sector. This equipment is truly next generation capability for rapid 3D printing of large aerospace parts.”

The DragonForge Series introduces several processing enhancements that are critical for printing high-quality aluminum alloys, particularly AA7XXX alloys such as Aluminum 7075, which are widely used in aerospace applications for their strength-to-weight ratio. Beyond hardware, Meld has invested heavily in software innovation.

Powerful simulationThe new machines feature enhanced autonomy, improved user interaction, and powerful simulation and monitoring tools. Among the most notable advancements is the introduction of a digital twin — a virtual replica of the physical machine which allows users to run code, simulate 3-D prints, and validate strategies before committing to a physical build. Operators can now identify potential delays, optimise parameters, and maximise efficiency, all before a single layer of metal is deposited.

Industrialising this technology in the DragonForge printers marks a significant step forward for domestic manufacturing. The machines are designed to reduce lead times, minimise floor space requirements, and lower energy consumption. For industries reliant on aluminum and titanium, the ability to deliver 3-D printed forgings on demand opens new possibilities for the repair and replacement of legacy components, as well as the production of critical parts in supply chains strained by a shortage of forged metal.

Nanci Hardwick continued: “For aerospace, space, and other aluminum and titanium dependent industries, where forging quality is mission critical, this means solutions can reach the market in weeks instead of months or years.”

The DragonForge Series is now available for Meld’s L3, K2, 3PO, and CD-14 platforms. With this launch, Meld aims to set a new standard for large-scale metal additive manufacturing (AM), offering the industry a path to faster, more flexible, and more sustainable production.