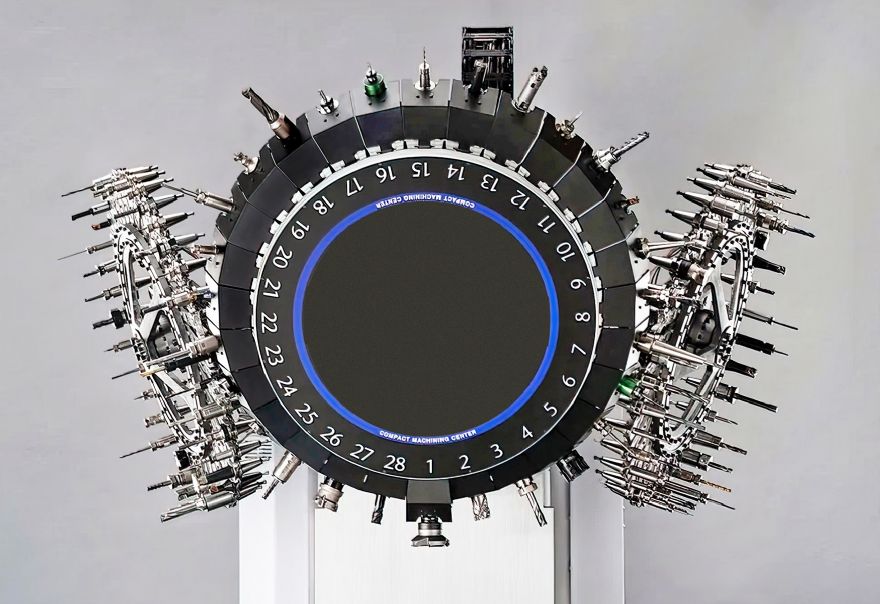

Twin 36-tool stockers positioned either side of the 28-tool turret magazine bring the total number of cutters available to 100

Twin 36-tool stockers positioned either side of the 28-tool turret magazine bring the total number of cutters available to 100At the recent

EMO 2025 show held in Hannover from 22 to 26 September, Japanese machining centre manufacturer Brother introduced a variant of its Speedio U500Xd2-5AX 30-taper, five-axis machining centre able to deploy 100 different cutting tools, without the need for manual intervention.

It addresses the accelerating industry trend toward high-mix, low-volume production and the need for prolonged periods of lights-out, unattended operation. Sole sales and service agent in Britain and Ireland is

Whitehouse Machine Tools, Kenilworth. Designed in accordance with Industry 4.0 principles, the U500Xd2-5AX 100T is aimed at sub-contractors and OEMs that are already converts to using the efficient face-and-taper BBT30 tool interface, or are receptive to its merits, as opposed to the continued use of more cumbersome 40-taper machines.

Pictured left: the working area of the Speedio U500Xd2-5AX 100T, which has a footprint of fractionally over 4m2

Pictured left: the working area of the Speedio U500Xd2-5AX 100T, which has a footprint of fractionally over 4m2Compelling reasons for adopting 30-taper platforms are the very high-speed axis motions, which minimise idle times and raise productivity, the typically 80% reduction in electricity and air consumption, and the compact footprint. Brother technology also delivers high reliability, maximising consistency of performance.

Previous limitations on tool capacity and process integration within a minimal space on a factory floor have been eliminated, and a side shutter for robotic loading and the availability of automated workpiece or pallet storage and handling equipment allows the formation of a fully automated production cell.

The tool count has been ingeniously boosted by mounting a 36-tool stocker on either side of the 28-tool turret magazine, enabling manufacturers to keep an unprecedented number of different tools, sister tools and special cutters ready for use, without operator involvement.

Despite the large tool storage capacity, the machine maintains its rapid 0.7sec tool-to-tool change time, while other top-end features also remain the same. They include a -30/+120deg swivelling trunnion carrying a 75rev/min rotary table, and generous axis travels of X:500 and Y:450mm with 50 m/min rapids, and 380mm in Z with 2.2g acceleration at up to 56m/min. As on the base machine, spindle speed is 12,000rev/min, or alternatively 16,000 or 20,000rev/min, and a further option is 70-bar instead of 20-bar through-spindle coolant.

The combination of an expansive working area, dynamic motion control, and high tool capacity allows operators to perform complete multi-face machining in a single clamping, simplifying workflow and reducing cumulative setup errors. Maximum table load is 100kg, so there is little restriction on the type of workpiece that machinists are likely to want to put on a 30-taper machining centre.

The new model is equipped with Brother’s latest CNC-D00 control system with 15in LCD touch panel, featuring enhanced functionality for fully interpolative five-axis machining, tool centre point control and automation interfaces. Support apps provide an overview of production and operational status, load monitoring, power consumption, tool set-up and adjustment, recovery support and cycle time optimisation.