Starrag

Starrag has launched the the ‘flagship machine’ in its versatile five-axis machining centre range that delivers exceptional precision and productivity for volume manufacturing. Building on the legacy of the Heckert HEC series, Starrag’s new Heckert X90 has arrived with a bold promise — to deliver unmatched performance in the machining of large components.

At the heart of this innovation lies a workpiece-side swivel unit, enabling dynamic five-axis machining from a single clamping position. This design not only enhances precision but also streamlines operations, making the X90 a formidable asset for manufacturers in aerospace, energy, and heavy industry.

“Speed is the name of the game,” says Starrag, pointing to the machine’s blistering 65m/min traverse rate and chip-to-chip tool change time of just 8.3sec. Pallet changes are completed in a mere 22sec, thanks to Starrag’s refined automation systems. The standard 800 x 1000mm pallets feature concave surfaces engineered to a curvature depth of 6 µm, ensuring stable and repeatable positioning even for the largest workpieces.

Despite its expansive capabilities, the Heckert X90 is also remarkably space-efficient, requiring 18% less installation area than its predecessor. With X, Y and Z axis travels of 1,750 x 1,300 (extendable to 1,400), and 1,400 (extendable to 1,800mm), the machine accommodates workpieces up to 1,600mm in diameter and 1,000mm in height, with a maximum load of 2,000kg. All this is housed within a compact footprint of just 8.9 x 4.6m.

The X90 offers a comprehensive spindle portfolio, from high-speed 15,000rev/min motor spindles to gear spindles designed for high-torque heavy-duty machining. Starrag’s dual tool change system supports both lightweight tools up to 22kg and heavy-duty tools up to 50kg, with maximum tool dimensions reaching 800mm in length and 325mm in diameter.

Competitive manufacturing landscapeTool magazine configurations are equally versatile, ranging from 45- and 60-position timing belt magazines to chain magazines holding up to 120 tools, and tower magazines with a capacity of 450 HSK-100 tools. This ensures the X90 is ready for extended unmanned production runs, a key requirement in today’s competitive manufacturing landscape.

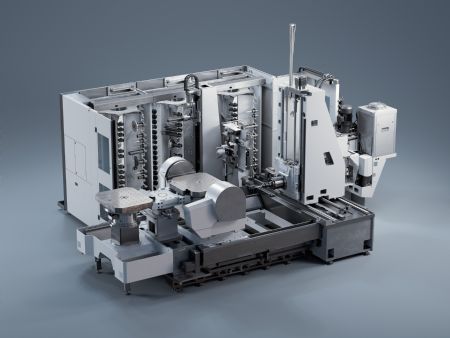

The Heckert X90 with guards removed

The Heckert X90 with guards removedTurning technology is seamlessly integrated into the machine concept, allowing users to perform both standard and complex turning operations with the productivity of a machining centre. Starrag’s approach offers flexible setup options, including vertical clamping and mid-operation repositioning via the pallet changer.

Operator experience has been elevated with a 24in touchscreen HMI powered by Siemens Sinumerik One. The glove-compatible, scratch-resistant interface allows access to construction plans and machining sequences, while an integrated camera maintains visibility into the workspace. Enhanced sensor technology and 13-channel clamping hydraulics further support automation, with optimised interfaces for pallet storage and robotic cells.

Chip management is another area where the X90 excels. A thermo-symmetric design, steep-angled fixed plates, and internal coolant supply up to 80 bar ensure efficient cooling and chip evacuation. For high-volume operations, the system offers flushing capabilities of up to 280 litres per minute.

The Heckert X90 is designed to integrate effortlessly with Starrag’s automation solutions, including round and linear storage systems and robotic cells. Its extended work envelope makes it ideal for automated production of large, complex components.

Starrag added: “The X90 is not just a machine — it is a platform for the future of large-part manufacturing.” With pallet compatibility across the X-series and legacy HEC machines, the X90 offers investment protection and operational flexibility. As the largest model in the expanded Heckert X-series — which includes the X50, X70, and X80 — the X90 stands as a testament to Starrag’s commitment to innovation, precision, and performance.