Wetherby-based

Taegutec UK Ltd has announced the expansion of its DIA-RUSH product family with new diamond-coated grades specifically engineered for machining composite materials and non-ferrous metals. This strategic product line expansion directly addresses the rising market demand for effective machining solutions for lightweight materials.

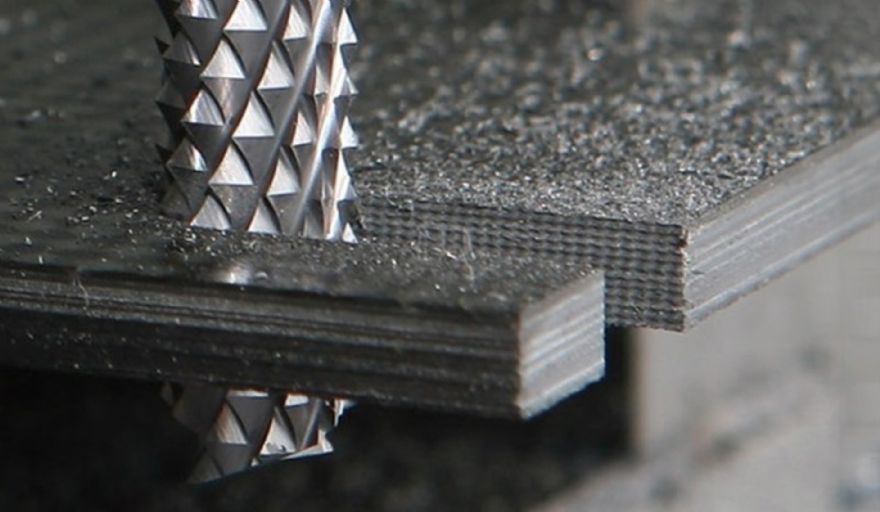

The three new grades feature TaeguTec’s advanced nano diamond coating technology, which introduces numerous nano diamond structures with extremely strong adhesion to the substrate layer. This innovative coating approach delivers hardness exceeding HV8000 and high thermal stability, impact resistance, and machining stability.

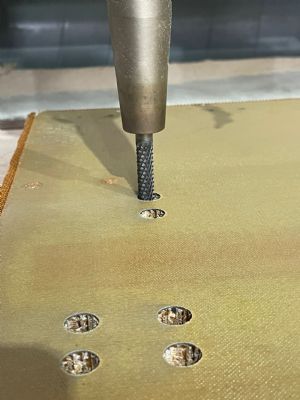

The expanded product lineup includes three specialised grades. The new TTD610 has been developed for composite materials such as CFRP, GFRP, and printed circuit boards that contain glass fibres, metals, and polymers. Compared to competitive solutions, the nano diamond coating significantly reduces delamination and achieves high hole accuracy in CFRP machining.

The TTD610 grade is applied to TaeguTec's RCME, RCDE, RRFE, RCOM, and RDCF solid carbide end mills, as well as the CDF, AES, and NHD series of drills, providing solutions for aeroplane frames, car chassis, and wind turbine blade applications. TaeguTec is said to be the world’s first carbide tooling manufacturer to have its own ‘in-house’ diamond coating chamber plant.

Complementing the TTD610, the new TTD620 grade has been optimised for graphite machining applications. This grade demonstrates excellent thermal stability during high-speed operations and delivers exceptional wear resistance for electrode and industrial part production. It replaces the previous TT6050 diamond-coated grade.

The TTD620 is available in TaeguTec’s DMB, DEB, DMR, and the DER ranges of two-flute ball nose, short ball, corner radius, and three-flute corner radius series of solid carbide end mills, as well as the APCT, 3PHT, and CCGT insert geometries.

The third new grade, the TTD630, has been introduced for machining ceramic and zirconium dioxide. It offers excellent wear and thermal shock resistance, featuring strong coating adhesion for demanding applications such as the machining of dental crowns. The TTD630 grade enables effective machining with HSB and HSF solid carbide end mills, as well as NHD solid drills for industrial and dental applications.