Affolter Group

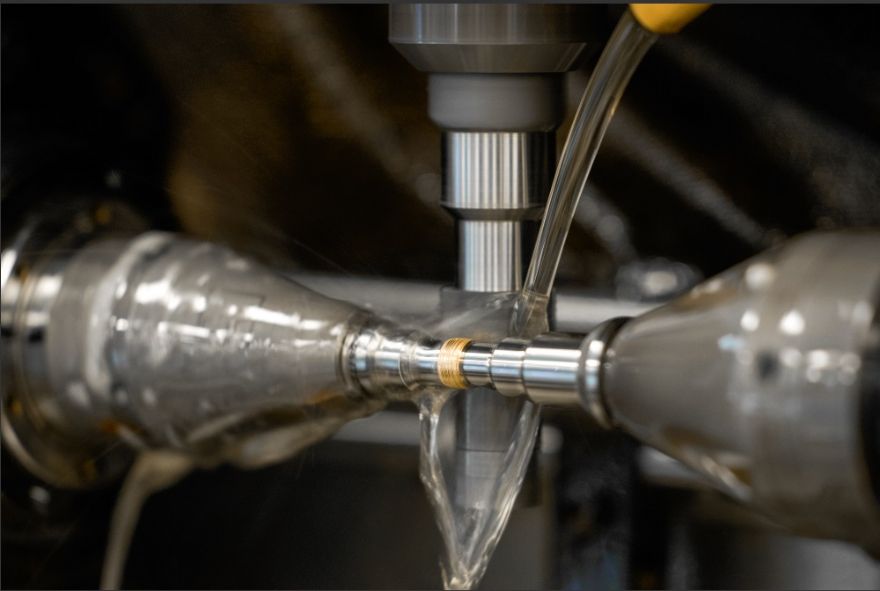

Affolter Group, a Swiss specialist in high-precision gear hobbing solutions, has unveiled its latest innovation — the AF140 gear hobbing centre. Designed for the production of small gears up to 40mm in diameter and with a maximum module of 1mm, the AF140 slots into the company’s portfolio as a replacement for the AF90 and AF100, combining the strengths of both while introducing a new level of automation and digital connectivity.

Developed in close collaboration with end users and industry partners, the AF140 has been engineered to meet the increasing demand for compact, versatile and user-friendly gear hobbing solutions. While tailored to the exacting requirements of the watchmaking industry, the machine is equally suited to applications in micromechanics, aerospace, automotive, micromotors, robotics and medical technology.

Mikael Affolter, head of sales at Affolter Group, said: “With the AF140, we are offering our customers a perfect balance between performance, flexibility, and innovation. Its compact footprint makes it ideal for workshops where every square centimetre matters, while its compatibility with existing loaders and the option of a robotic arm provide new levels of automation and productivity. Combined with remote service features, the AF140 represents a true step forward in precision gear hobbing.”

The AF140 is capable of cutter rotation speeds up to 16,000rev/min and workpiece rotation speeds of up to 5,000rev/min. A newly developed robotic arm option enables automatic loading and unloading, paving the way for continuous, unattended production. The machine remains compatible with a wide range of existing accessories, including W20, W25, W31 and AF45 loaders, as well as deburring units.

Built on Affolter’s Pegasus CNC platform, the AF140 offers seamless digital integration via IO-Link sensors, simplified commissioning, and advanced remote service capabilities for real-time diagnostics and updates. With this launch, the company has streamlined its product range to a focused two-machine portfolio — the AF140 and AF160 — ensuring greater clarity and efficiency for customers.

Mr Affolter concluded: “This simplification of our product portfolio further enhances our customer service capabilities, strengthens operational efficiency, and creates a solid foundation for growth and innovation in the coming years.”