To provide manufacturers of complex turned and milled components up to 80mm in diameter with an exceptional level of flexibility, accuracy and productivity, Bushey-based

Citizen Machinery has introduced the third-generation Miyano ABX-80THY, a fixed-headstock, bar-fed lathe equipped with three turrets, each of which has 80mm of movement in the Y axis.

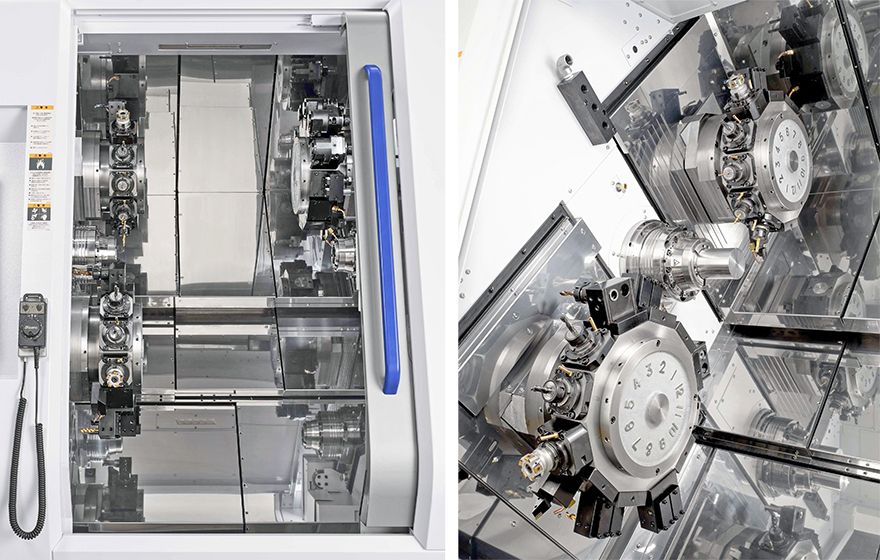

Positioned above the centreline of the workpiece spindles, two of the turrets are mounted on box guideways and are dedicated to the 80mm capacity main spindle and the 65mm capacity sub-spindle respectively. Meanwhile, the lower turret is able to serve either spindle and all three tool carriers accommodate up to 12 static or live cutters. Maximum workpiece diameter for chuck work is 165mm.

High power prismatic machining is a defining feature of the lathe, as all 36 turret positions are rated at 4.5kW, deliver up to 40Nm of torque and achieve a rotational speed of 6,000rev/min. It means components requiring multiple operations can be completed in a single setup, eliminating secondary processes and improving both throughput and consistency.

Simultaneous cutting with all three turrets drastically reduces cycle times and the lathe maintains Miyano’s hallmark rigidity and precision for high accuracy machining. The capability to perform front and back working concurrently makes the machine ideally suited to industries such as aerospace, medical, automotive and precision engineering generally, where intricate geometries and tight tolerances are commonplace.

Maximising production efficiencyThermal stability was key in the development of the ABX-80THY. Temperature variation across the machine structure is constantly monitored by integrated sensors and intelligent software automatically adjusts the axes to compensate for any movement, reducing thermal displacement from around 30µm to just 10µm. It ensures round-the-clock accuracy, even during extended periods of unattended operation, safeguarding quality standards and at the same time maximising production efficiency.

Citizen also placed emphasis on ease-of-use and operator support. The control system provides intuitive access to tool setting, cycle time monitoring, spindle synchronisation and adjustment, and maintenance functions. The GUI (graphical user interface) makes it simple to manage tool offsets and zero-point adjustments, ensuring fast set-up and minimal downtime. Optional tool monitoring further enhances reliability by automatically stopping the machine if excessive tool load is detected, preventing damage and scrap.

In keeping with Citizen’s focus on lights-out production, the lathe is equipped with a programmable, servo-driven parts catcher capable of handling components from both spindles and transferring them via a parts conveyor. Chip conveyor options enable continuous running across different materials and cutting conditions. An optional touch probe tool setter in the machine ensures accurate cutter measurement and is simple to remove thanks to its magnetic coupling.