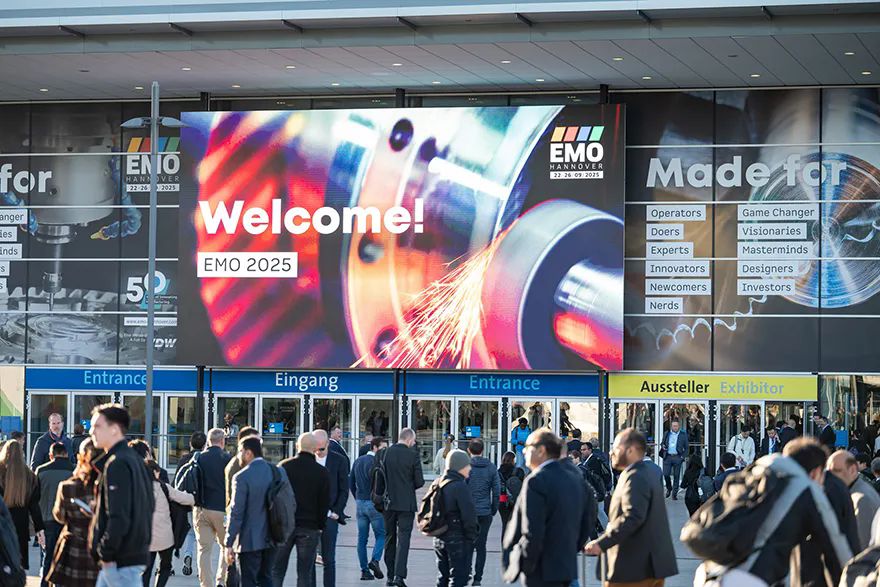

Trade visitors from all over the world enjoyed important innovation impulses and inspiration at EMO 2025

Trade visitors from all over the world enjoyed important innovation impulses and inspiration at EMO 2025For five days in September, Hannover became the epicentre of global metalworking as 80,000 trade visitors from around the world descended on

EMO Hannover 2025. The exhibition grounds buzzed with innovation, with automation and artificial intelligence (AI) taking centre stage as key drivers of production efficiency. These technologies, now deeply embedded in industrial processes, are reshaping the future of manufacturing.

EMO has stood for technology, information, exchange, and international cooperation for over half a century. This year, more than 1,600 exhibitors from 45 countries showcased a wide variety of solutions aimed at modernising and upgrading production.

Carl Martin Welcker, general commissioner of

EMO 2025, said: “There is a profusion of smart and impressive technical solutions. This year’s show has convincingly demonstrated that.” However, he cautioned that investment is needed to unlock their full potential. “Many projects are in the pipeline after three years of investment restraint, but the uncertainty in the political sphere continues to put the brakes on investment.”

Pictured right: EMO 2025 is promoting automation for more competitiveness worldwide

Pictured right: EMO 2025 is promoting automation for more competitiveness worldwideWhile domestic investment in Germany remains subdued, confidence is growing abroad. Two-thirds of international visitors indicated plans to invest, compared to less than half of German visitors. This sentiment is reflected in the latest figures from the German machine tool industry, which saw a 6% rise in export orders in the first seven months of 2025, while domestic demand fell by 22%.

Despite this, exhibitors reported strong sales. Norbert Teeuwen, managing director of

Okuma Europe, said: “Open possibilities — that is precisely what connects

EMO and Okuma. Our appearance at the exhibition was a complete success — among plenty of sales, we even sold three exhibition machines directly off the stand.”

Automation emerged as the dominant theme, driven by rising costs and a shortage of skilled labour. Half of the visitors surveyed expressed interest in using automation to boost productivity. Aaron Morrill, a CNC mechanic from the USA, said: “Automation is everywhere here and is going to make a big difference.” Around 140 robot manufacturers were present, underlining the growing importance of robotics in the machine tool industry. Klaus Winkelmann,

Fanuc Europe CEO, said: “We also see that robots will become increasingly important in the machine tool industry. Industrial robots will coexist with human operators. In the future, they will provide the most efficient solutions.”

Keen to explore new developmentsDigitalisation and AI also drew significant attention, with over a third of visitors keen to explore new developments in these areas. Jan Otoupakik, CEO of Czech startup

4dot Mechatronics, explained: “We see added volume in processes where all the possibilities for processing data from sensors are utilised. AI is useful for this and improves quality in the factory.” The popularity of the daily

P.O.P Talks on the central innovation stage further highlighted the growing interest in AI’s role in production.

These technologies are not only enhancing productivity and quality but also contributing to sustainability. Professor Berend Denkena from

Leibniz University Hannover shared a compelling example: “We are working on various solutions. One very important one is to reduce the energy consumption of production systems, for example by reducing the coolant flow so that only as much coolant as necessary is used, rather than as much as possible, which was the strategy in the past. This allows us to save up to 95% of the pump energy, electrical energy and up to 60% of the total energy consumption of the production system. So, this is a big step forward.”

Pictured left: technology, information, exchange, international networking and cooperation — this is what EMO has been all about for 50 yearsEMO

Pictured left: technology, information, exchange, international networking and cooperation — this is what EMO has been all about for 50 yearsEMO once again proved to be a top platform for international managers and buyers, with more than half of visitors holding top or middle management positions and possessing procurement authority. Satisfaction levels were high, with 94% of visitors achieving their objectives and 98% rating the event between satisfactory and very good.

Exhibitors echoed this positive sentiment. Irene Bader, a board member at

DMG Mori, said: “What we presented at

EMO in 2025 is a glimpse into the future of production. Our customers’ enthusiasm and their valuable feedback have once again shown us how important face-to-face exchange is for real innovation.”

German Wankmiller, chairman of the board of management of

Grob-Werke, added: “Overall, we are satisfied with how

EMO Hannover 2025 went, and we have been positively surprised considering the currently challenging market situation. The number of visitors and the quality of the discussions have also been consistently positive and have given us important ideas to follow up over the coming months.”

Dr Markus Heering, executive director of the

VDW, which organises

EMO, concluded: “Once again, it has proven possible to attract international market leaders in metalworking to

EMO and address the new topics in industrial production. As a result, the show has consolidated its position as the world’s leading trade fair and barometer of trends.”

EMO 2027 is due to take place from 4 to 8 October in Milan, Italy.