In today’s competitive manufacturing landscape, digitalisation is no longer a luxury — it is a necessity.

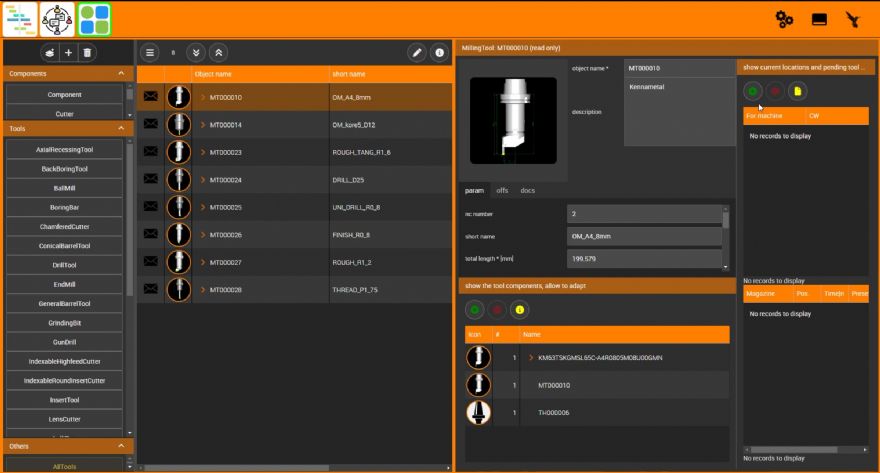

Open Mind Technologies, a recognised leader in CAD/CAM and MES solutions, is responding to this demand with a new addition to its portfolio — a comprehensive digital tool management suite. Designed for manufacturers using hyperMILL or other CAM systems with a tool database, the suite is centred around the ‘Tool Logistics’ module within the Hummingbird MES, enabling streamlined and highly efficient tool management in just five steps.

Tool management inefficiencies — such as lack of transparency, excessive stock, and premature tool changes — can lead to costly downtime and operational delays. Open Mind’s approach tackles these issues head-on, offering a structured path to digital transformation that begins with a thorough analysis and ends with intelligent, automated control. The journey starts with a ‘deep dive’ into current operations. Existing processes and systems are reviewed, from tool availability and storage data to setup workflows. This diagnostic phase identifies areas for improvement and lays out a clear roadmap for implementation, including system architecture and role assignments.

Next comes data standardisation. For any digital tool management system to function reliably, the tool database — whether in hyperMILL or another CAM system — must be clean and consistent. Open Mind supports this step through a dedicated workshop, ensuring that the foundation is solid before integration begins. System integration follows, where all modules are configured and tested in a development environment. The hyperMILL interface is plug-and-play, while other connections — to machines, presetting devices, and more — are tailored and validated. Comprehensive training ensures that users are ready to hit the ground running.

Once the system is commissioned, coaching and support help teams adapt quickly. The Hummingbird ‘Tool Logistics’ module takes centre stage, managing everything from tool life and measurement to storage and logistics. Operators can also feed back real-world data, such as deviations in cutting values or tool wear, enhancing the system’s responsiveness.

Finally, the results are checked and validated. Success is measured not just in reduced tool variety or improved usage, but in the potential for further integration. Cabinets can be connected, machines can communicate directly via OPC UA, and bidirectional data exchange between Hummingbird and the machine tool opens the door to full automation. This modular approach also allows for the gradual rollout of additional MES components, driving even greater efficiency.

At the heart of this system lies precise, well-maintained data. The hyperMILL tool database, paired with TOOL Builder, provides the ideal environment for consistent data usage. Thanks to integrated synchronisation, this data flows seamlessly into Hummingbird—no extra interface required.

Maximilian Waizenegger, director of business development at Open Mind Technologies AG, said: “The actual management of the tool inventory is then carried out entirely in Hummingbird. Our specialists provide support in maintaining the database and implementing the manufacturing processes. In this way, they create a comprehensive solution from which our customers benefit in the long term — all from a single source.”