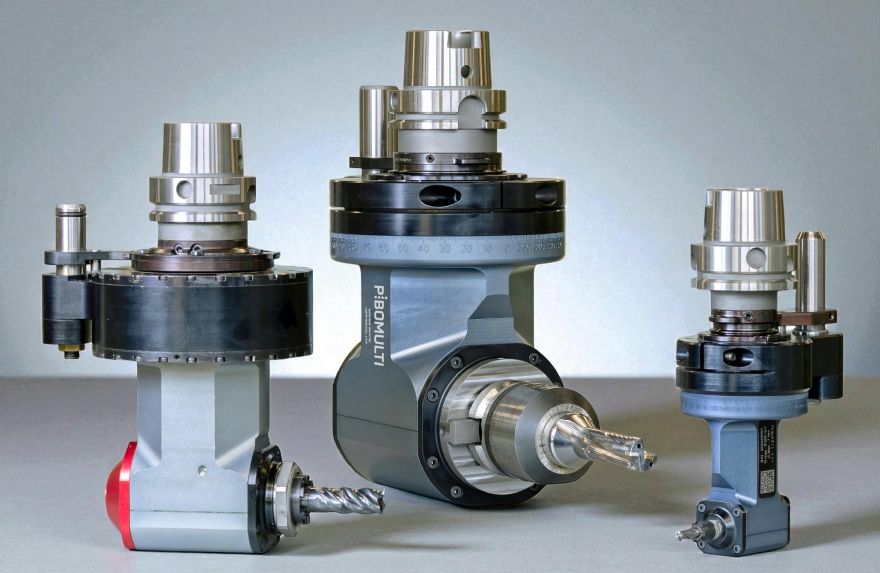

Three models from the new Pibomulti CEP-NG range of right-angle heads, available in the UK and Ireland through sole sales agent Gewefa UK

Three models from the new Pibomulti CEP-NG range of right-angle heads, available in the UK and Ireland through sole sales agent Gewefa UKA new range of tool-holding heads designed to mill and drill components at right angles to the orientation of a machining centre spindle has been introduced by Swiss manufacturer

Pibomulti, whose products are sold into the British and Irish markets exclusively by

Gewefa UK. The next-generation CEP-NG heads can likewise be used in the B-axis spindle of a multi-tasking lathe, or in a live VDI turret station of a turn-mill centre.

Built with high-quality, hardened and ground bevel gears and ABEC 9 angular contact bearings, CEP-NG heads are engineered to deliver reliability, performance, precision and longevity, even when tackling challenging applications in demanding sectors such as automotive, aerospace, medical, defence and energy.

Compared with previous models, the new generation of heads is capable of transmitting higher rotational speeds at a 1:1 ratio, leading to greater productivity due to raised metal removal rate when roughing, or finer surfaces when taking finishing cuts. The CEP-NG 17 model, for instance, which clamps the cutter in an ER25 collet, can reach a maximum speed of 5,000rev/min, optionally 6,000rev/min, and has a maximum torque of 50Nm.

ER8 up to ER50/ISO40 tool clamping is available, the latter being capable of deploying a 36mm diameter tool and transmitting 210Nm of torque. A further benefit of the head redesign is that vibration is lower, especially when tool overhang is long, further promoting good surface finish as well as extending tool life.

Quicker tool changePibomulti CEP-NG heads are also lighter in weight, reducing stress on the machine tool spindle bearings, as well as on the machine structure when the spindle head is accelerating or decelerating in the linear axes. The lightness similarly lessens the load on the magazine arm during automatic tool change and allows quicker exchange.

Lower head weight equally promotes faster cutting feed rates and rapids due to a decrease in inertia, contributing further to elevated levels of production output by shortening overall cycle times. All these advantages are particularly beneficial, including in terms of lower maintenance costs, if the machine is small, less rigidly built or old.

The latest head series integrates several advanced options, including up to 100-bar coolant delivery through the head. A 360deg indexing ring with graduations delivers flexibility for complex, multi-sided machining tasks by allowing the machine tool to automatically rotate and lock the cutting angle. Alternatively, the ring can be indexed manually into position.

Suitable for automated production cycles and unattended running, the feature avoids the expense of having to buy multiple special heads or wasting time manually repositioning a part. Additionally, the standard Pibomulti CEP-NG head range is customisable to meet specific customer needs. A range of interfaces is offered, including HSK, ISO, CAT, BT, CAPTO and VDI.