Seco

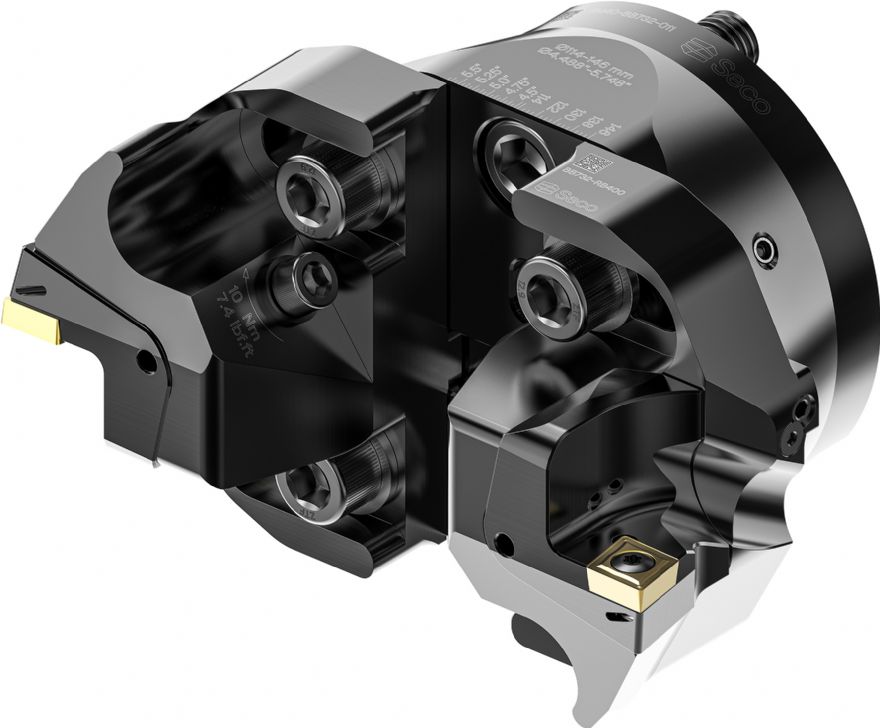

Seco has launched the new line of BB732 boring bridges, a modular solution designed for deep boring operations with Steadyline bars. Engineered for both roughing and finishing tasks, BB732 bridges deliver ‘vibration-free performance, optimal coolant flow, and exceptional surface finish all in one tool’.

The BB732 boring bridges are tailored for use with the Steadyline SM40 shell mill holder, supporting diameters from 114-301mm for roughing and up to 315mm for finishing. The conical-reinforced shape of the holder ensures high static and dynamic rigidity, up to three times greater than solid holders, while the Steadyline vibration damping system enables stable, high-precision machining even in demanding conditions.

Kavita Dandge, global product manager machine solutions, said: “The BB732 boring bridges are designed to work seamlessly with Steadyline bars, especially the SM40 series, for deep boring jobs with larger diameter bars. One of the standout features is the optimised coolant flow – it is directed right at the cutting edge to help break up chips and keep the insert cooler.”

The BB732 bridges eliminate the need for separate tools for roughing and finishing, reducing inventory and setup time. With a built-in safety stopper to prevent block ejection due to centrifugal force, the system also prioritises operator safety.