norelem

norelem has expanded its portfolio with a range of premium C‑profile mounting rails and accessories designed for machine and plant engineering applications. The cold‑formed steel profile rails, commonly referred to as installation rails, are intended for fast, precise installation of components, cables, sensors and assemblies.

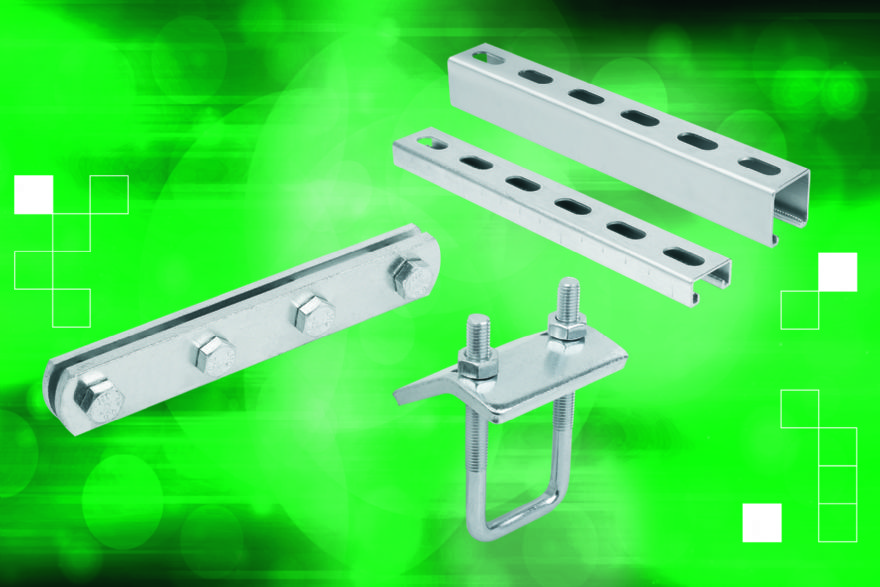

The rails are available in system sizes 28 (28 × 15mm and 28 × 28mm) and 41 (41 × 22mm and 41 × 41mm). Their C‑profile geometry provides high flexural and torsional rigidity, enabling them to safely absorb tensile and transverse loads perpendicular to the rail axis. System 41 also features a pronounced serration to secure threaded plates and T‑head bolts, even under significant transverse loading. A large number of slotted holes allows rapid mounting of items such as profile feet, T‑head bolts, threaded plates, rail connectors, brackets and beam clamps. Combined with matching accessories, the rails form a versatile installation system, and can be cut to length where required.

Almir Jakupovic, sales manager at norelem, explained: “The system offers an exceptional degree of versatility. Attachments can be freely positioned and adjusted in an infinitely variable way. Construction elements can be adapted to fit new bearing and fastening requirements as they can be replaced, retrofit or moved at any time.”

The mounting rails are supplied in standard lengths of 1,000, 2,000 and 3,000mm, with custom lengths available on request. Manufactured from galvanised steel, they offer the robustness and corrosion resistance necessary for harsh industrial environments.

Typical applications include machine and equipment frame construction, mounting motors, sensors, measuring systems and actuators, and guiding hydraulic, pneumatic and electrical cables and hoses. The rails can also be used in electrical engineering for cable carriers, ducts and risers, as well as in building services for heating, ventilation, air‑conditioning and pipeline installation.