When manufacturers are considering their next invest, Phil Cattaneo, Coventry-based

www.ncmt.co.uk NCMT’s business development manager (automation), says: “Installing automation is all about fixing bottlenecks. There is no point having automation if there isn’t a problem.” It is a refreshingly pragmatic stance in a market often dominated by headline technology.

For NCMT, which also has a regional office in Leatherhead, automation is not about robots for robots’ sake, nor about chasing the latest trend. It is about understanding where productivity is being lost and then designing a solution that delivers real, measurable improvement. There is no ‘one-size-fits-all’ approach. In fact, one of the most uncomfortable truths in manufacturing is that many machines are productive for far less time than businesses believe.

Machines with no automation typically achieve just 25–30% spindle uptime, with lost capacity absorbed by non-value-adding activities such as waiting time, part setting, tool changes, human error and simply being out of shift. NCMT automation projects usually begin with a tour of the shopfloor rather than a discussion about equipment.

Mr Cattaneo explained: “One of my favourite things to do when I visit a new customer is just to let them take me around the shopfloor. The light towers on top of the machines tell you everything you need to know about how productive the factory really is. Typically customer will tell you they are running at about 60% capacity. But when you actually look, one or two machines are running at 10%. That is when the conversation really starts.”

Evidence-led approachThis practical, evidence-led approach helps manufacturers see the gap between perceived and actual utilisation. From there, NCMT works backwards to identify what is really constraining output whether that is manual machine tending, long setups, inconsistent processes, material-flow issues or the inability to run unattended. Mr Cattaneo continued: “It can be daunting knowing where to start with automation. There are so many solutions available. Our role is to strip it back and focus on what will make the biggest difference for that business.”

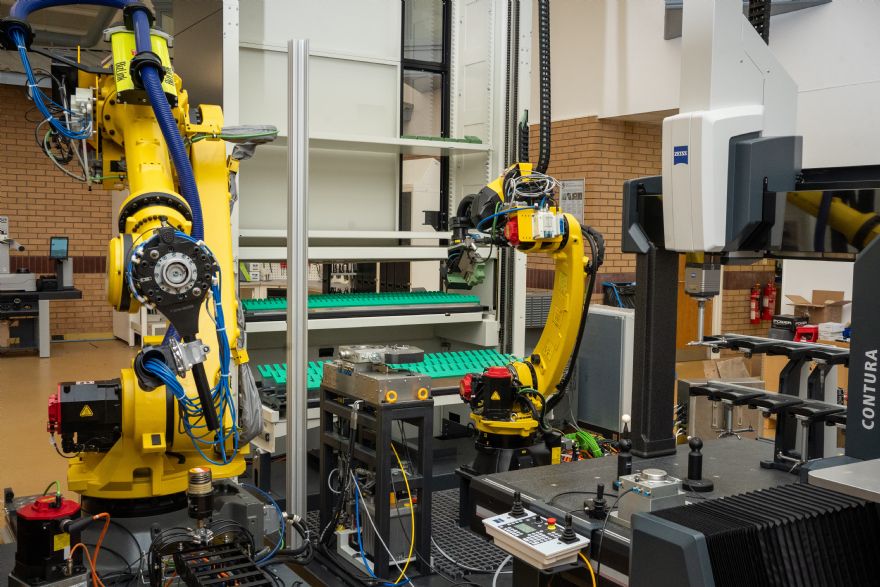

Drawing on decades of hands-on experience delivering everything from single-machine robot cells to complex, multi-million-pound flexible manufacturing systems, NCMT has developed a clear set of guiding principles for manufacturers beginning an automation project in 2026. These principles are shaped by real-world implementation, not theory, and are designed to help businesses invest with confidence, avoid common pitfalls and unlock sustainable productivity gains.

The temptation to begin an automation journey by specifying a robot, pallet pool or transfer system is understandable, but it is often the wrong place to start. At NCMT, automation is viewed first and foremost as a way to resolve specific production constraints, not as a technology exercise.

The most effective projects begin by identifying where time, capacity or consistency is being lost. That may be excessive waiting time between cycles, lengthy set-ups, inconsistent quality, or the inability to run unattended outside normal shifts. Once those issues are clearly understood, the appropriate automation solution naturally follows.

This problem-led approach often requires challenging assumptions. In one project, a manufacturer was intent on fully automating every step of a process, including the installation of a very small, intricate pin. Automating that single operation would have added around £1 million to the system cost. By stepping back and re-assessing the true value, it became clear that a simple manual operation at the end of the line achieved the same output without affecting throughput or return on investment.

The lesson is simple: almost anything can be automated, but not everything should be. The focus must remain on whether automation genuinely adds value to the overall process.

Think modular and build confidenceAnother common pitfall is trying to automate too much, too quickly. NCMT advocates a modular approach, targeting low-risk, high-return opportunities first and building capability over time. Rather than attempting a fully automated factory from day one, manufacturers can start by addressing a single bottleneck. For example, automating machine tending on a constrained asset or introducing a pallet system to eliminate waiting time. Once that initial step is proven, the solution can be expanded incrementally.

This staged strategy improves return on investment while also building internal confidence and skills. NCMT has supported customers who began with a single automated cell and later expanded into multi-machine lines supported by advanced production management software, all without disrupting existing operations.

One recent project involved a transport-sector manufacturer that invested in an automated line with two machines, designed from the outset to accommodate a third machine as demand grows. NCMT decommissioned the existing layout, reconfigured the shopfloor and installed a flexible automation system that can scale over time. It is a clear demonstration of automation as a long-term investment, not a one-off cost.

Design for stability, not headline speedIn lights-out production, reliability consistently outperforms raw cycle time. A common misconception in manufacturing is that faster is always better. In reality, an aggressive process that stops overnight can wipe out hours of potential output.

Automation fundamentally shifts priorities. A slightly slower but highly stable process, capable of running unattended for long periods, will always deliver more value than an unstable high-speed process. This is particularly important in transfer lines and multi-machine systems, where each station is designed for repeatability and consistency rather than maximum flexibility.

Consistency underpins everything: predictable quality, controlled tool wear and reliable output. Automated systems excel at performing the same task, in the same way, every time. That repeatability is what enables manufacturers to achieve dependable lights-out production and maximise the return from their automation investment.