@MillsCNC #engineering #tooling #manufacturing @qualiturn Established in 1974 as a precision sub-contract specialist, Hertfordshire-based Qualiturn Products Ltd has built its reputation on quality, reliability, speed of delivery and cost-competitiveness.

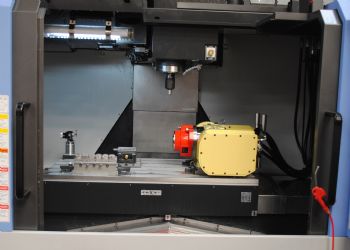

The company regularly invests in the latest machine tools and manufacturing technologies, and it recently (in August) acquired its first vertical machining centre — a Doosan DNM 650 (with rotary/tilting table) from Mills CNC

(www.millscnc.co.uk). This large-capacity machine, equipped with a 30-position ATC and a Nikken fifth-axis unit, represents an important milestone for the company.

Managing director Nick Groom says: “We supply high-precision turned and milled parts to a diverse range of customers operating in the gas and oil refining, medical, aeronautics and aerospace, leisure, construction and hydraulics, electronics, lighting, automotive and agricultural sectors — to name but a few. We machine parts from prototypes and one-offs through to large-volume series from an equally diverse range of materials.

"Until August, our machining capabilities were delivered by our fixed-head and sliding-head lathes, which allow us to mill complex features on what are essentially turned parts. However, talking to customers about their future machining requirements made it clear that there was potential for us to grow the milling side of our business if we increase our capability. That’s what drove us to invest in a dedicated stand-alone machining centre.”

The choice of Doosan technology was influenced by a number of factors. Qualiturn needed a large-capacity machine that could cope with heavy-duty high-volume metal removal as well as fine-finishing operations, and it wanted to move into five-axis machining. The DNM 650, with its integrated fifth-axis unit, can machine complex parts in one set-up.