SmartCAMcnc has announced the release of SmartCAM v2019. This provides new Adaptive Solid Pocket and Solid-Planar Processes in the SmartCAM Advanced Milling, Advanced Turning and Freeform Machining applications (

www.SmartCAMcnc.com).

Also included are many customer-requested changes to the SmartCAM user interface and core functionality.

Additionally, various improvements to NC code generation provide added flexibility.

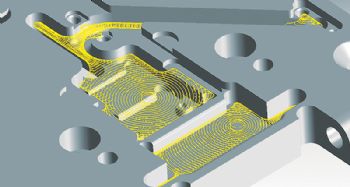

The new Adaptive Solid Pocket Process is used to create consistent-engagement high-speed rough-milling tool-paths when pocketing on solid or surface models.

Meanwhile, a new Adaptive Solid Planar Roughing Process has also been added to the Adaptive Milling Tool-path Modeling task set, which is used to create consistent-engagement high-speed rough-milling tool-paths when it is required to remove material from a stock volume on solid or surface models.

The models may consist of any combination of core and cavity features, with open or closed, blind or through regions, as well as any number of islands and ‘shelves’.

The process can be used for roughing simple prismatic parts through to complex-surface moulds and dies.

SmartCAM v2019 benefits from detail changes that provide a further refined and refreshed appearance, as well as improved ease of use.

For example, the size of an individual toolbar is easily set by right-clicking on it and using the fly-out menu to select a large, medium or small setting for that toolbar, while an option has been introduced to allow the display of text around the icon used on toolbar buttons.

Furthermore, a Toolbar Set stores the toolbars that are enabled in the user interface, where they are located on-screen, their orientation and the icon size for each — and there is now the ability to zoom the graphics view.

With regard to improvements to NC code generation, these include: a new code generator section for milled-hole (as opposed to drilled-hole) machining operations; the ability to set decimal, integer and string macro variables during code generation; and improvements to ‘wrapped geometry handling’.

Furthermore, SmartCAM v2019 NC applications are now available in both 32-bit and 64-bit versions (the latter making better use of modern computer hardware, allowing it to run applications quicker and address more RAM memory), while the SmartCAM Advanced Wire EDM roughing and finishing operations now include new wire-guide offset inputs.