The latest version of WorkNC from Hexagon Manufacturing Intelligence’s Production Software business (

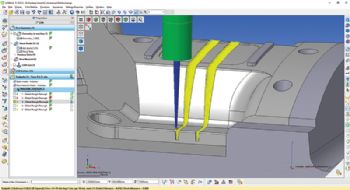

www.HexagonMI.com) expands its ‘Advanced Toolform’ technology with the introduction of five-axis machining for any tool shape. WorkNC 2020.0 allows for five-axis tool shapes — such as barrels, ovals, parabolics or any given shape — to be calculated over the part surfaces, including negative offsets.

Miguel Johann, WorkNC brand manager, said: “This is the perfect complement to the well-established three-axis finishing tool-paths.

“Also known as circle-segment tools, these revolutionise machining productivity at all levels by bringing the benefits of a smoother contact point and larger step-overs.

“Moreover, accessibility is not compromised, as the shank diameter can be kept relatively small.

"They bring the benefit of a smoother contact point, resulting in larger step-overs without compromising accessibility, as it keeps the shank diameter relatively small.

"Meanwhile, WorkNC’s Advanced Toolform solution allows for multiple surfaces to be machined at the same time, based on CAD models coming from any source — solid or surface based.”

"Furthermore, the Wall Machining tool-path has been enhanced by including the Spiral Patterns and 2-D tool-path compensation; sharp edges are now protected by a corner-smoothing radius and retracts have been optimised to increase productivity and reduce machining time.

“Customers will benefit from performance improvements achieved in this version, specifically on the Waveform roughing tool-path, on holder and five-axis machine collision checking, and 3-D stock initialisation.

“Technology is always expanding in all areas of the product.

"Finishing tool-paths can now handle bottom stock allowances, and the Global Roughing tool-path can now access more-difficult regions by allowing minuscule shank approximations.”