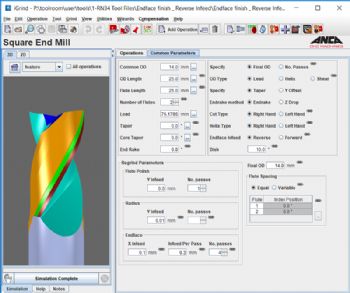

Thomson Mathew, software product manager at the tool and cutter grinder manufacturer Anca (

www.machines.anca.com), said: “ToolRoom RN34 is aimed to be the differentiator for many end-mill manufacturers by allowing them to design complex geometries through software to achieve increases in tool life, productivity and cutting volume, as well as quality and precision of the workpiece.”

Mr Mathew says the new software promises improved productivity (through the intuitive creation of complex end-mill geometries), improved tool balance and minimised chatter (via the simple design of high-performance complex tools). Moreover, ToolRoom RN34 supports both manufacturing and regrinding applications.

New ball-nose cycles allow users to manufacture a range of ball-nose tools suitable for finishing and roughing, with the new ‘designer edge’ accommodating high helix angles on ball cutting edges for better fracture-resistance and reduced vibration ‘due to the irregular curve’.

Meanwhile, a ‘double corner radius’ capability allows the design of barrel-shaped or lens-shaped tools with ‘larger to smaller’ or ‘smaller to larger’ radius from the end of the tool.

Vibration and deflection are reduced with this style of geometry, and the thinner chips that are formed are said to ensure longer tool life and enhanced cutting performance.

Tool balancing is provided on variable-helix and variable-pitch or single-flute tools to minimise the eccentric weight distribution when undertaking high-speed machining.

The benefits include reduced noise and vibration, improved machine bearing life and better surface finish.

The software also provides new ‘fluting cycles’ for manufacturing variable-helix and variable-pitch tools to eliminate the harmonics caused during high-speed machining by varying the time intervals between the flute contact with the workpiece; and a new ToolType is available from the end-mill ‘wizard’ to manufacture lollipop cutters of the type widely used in the aerospace and die/mould industries.

There is also a new feature in ‘End-mill’ cycles for adding OD chip-breakers, plus support for a wide range of constant-helix, constant-lead and shear cutters widely used in the aerospace and power generation industries.

Other new features in the software include a ‘wizard’ ToolType for countersink tools that supports standard flute and ‘fan gash’ flute styles.

Furthermore, the manufacture of a variety of thread-mills is now possible, while pocket-grinding software allows users to quickly and easily define PCD pocket geometries.