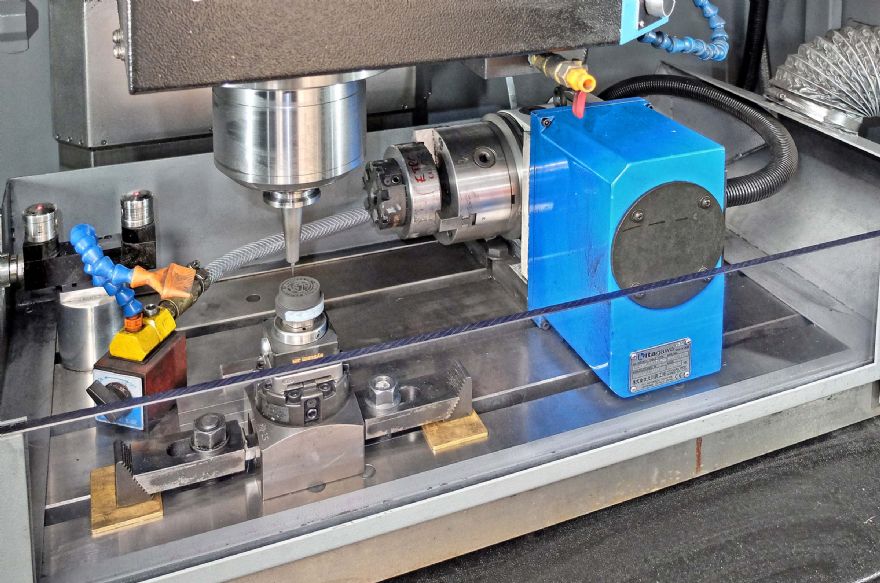

An enclosure mounted on the table of the VM10HSi at the Scottish engineering and tool-making company has air extraction to remove graphite dust

An enclosure mounted on the table of the VM10HSi at the Scottish engineering and tool-making company has air extraction to remove graphite dustA Scottish precision-engineering company and tool maker to the plastics industry has doubled its turnover since 2014, when it embarked on a programme of renewing its production equipment. Most of the investment went on four machine tools from Hurco — three machining centres and a CNC lathe — along with two new CNC die-sinking EDM machines from another supplier.

The engineering firm works ‘round the clock’ servicing a number of industries, including automotive, defence, medical, pharmaceutical, plumbing, food and drink, and electronics. It designs and manufactures a variety of tools, from single-impression prototype moulds to multi-impression production tools.

Half of the business comes from manufacturing highly decorative injection moulds that produce plastic caps and closures for premium bottles of whisky, gin and other spirits for which Scotland is world-famous (customers

are also to be found throughout the rest of the UK and Ireland).

These closures involve artwork and lettering that require intricate milling with ball-nose cutters — sometimes as small as 50µm in diameter — held in heat-shrink ‘back ends’.

Due to the small size of the cutters and the hardness of the tool steels processed (these include P20, Orvar Supreme, 113 grade and D2), designs are generally machined into graphite EDM electrodes for subsequent die sinking into the mould.

This achieves maximum quality, but hard-wearing copper electrodes are sometimes used for longer production runs.

A spokesperson for the company said: “Much of the very fine milling is done on our Hurco VM10HSi machining centre. Installed in 2018, it is fitted with a Kitagawa rotary-table fourth axis, a 30,000rev/min spindle and an enclosure mounted on the table with air extraction to remove graphite dust from the working atmos-phere.

“We also use this machine for high-speed milling directly into hardened materials, which we are doing more frequently.”

Boosting machining capabilityInvestment in the first Hurco machine (in 2014) was prompted by the tool maker’s wish to modernise its prismatic machining capability and — in particular — to bring previously sub-contracted bolster production in-house. The VMX42i with its 1,066 x 609 x 609mm work envelope and rotary table reduced the bolster manufacturing lead time from 10 weeks to three.

Moreover, the rigidity of this machine (as with all the Hurco machines at the Scottish company) means that it is also used for the hard milling of mould cavities, using the fourth CNC axis; they were previously machined in their soft state, sent out for hardening and then ground.

The other machining centre installed was smaller — a VMX30i with a 762 ¥ 508 ¥ 609mm work envelope. It arrived in 2016 to take some of the load off the VMX42i, as bolster production was being affected by the machine’s suitability for machining cavities in pre-hardened steel.

The latter work is now the province of the VMX30i, while the larger machine has been returned to its original purpose of producing bolsters. Some aluminium blow moulds are also machined on both these machines.

The reason for adding a Hurco TMX8i turning centre in 2015 was to supplement a pair of CNC lathes from another supplier and upgrade the manufacture of mould inserts, cavities and cores. Due to its rigid construction, this machine is also used extensively for hard turning of materials up to 68HRC; it minimises — and can sometimes eliminate — the need for subsequent polishing of parts.

Regarding the company’s choice of Hurco machine tools five years ago to start upgrading its capacity, the spokesperson pointed out that a lot of the manufacturer’s machines were — and still are — being installed in Scotland, which gave his company confidence (and provided many local reference sites).

Staff also knew from other customers and through visits to exhibitions that this brand of machine is ideally specified for the tool-making industry. Trials were carried out in Hurco’s technical centre at its High Wycombe showroom (

www.hurco.co.uk), and the decision was taken to opt for these machines to move forward with the upgrade programme.

In terms of offline software, the Scottish firm uses Delcam CADCAM plus Powermill CAM for 3-D work. Solid models from customers are imported to create cutter paths for post-processing, the final programme being transferred to the Hurcos either via a network or a USB stick.

However, a fair amount of conventional programming at the WinMAX controls is carried out on the shopfloor, to take some of the load off the CADCAM department. As an added bonus, WinMAX can read DXF files, which can be taken directly from CADCAM and imported to the Hurco control to define complex profiles without the risk of introducing human error.

The ‘legacy’ equipment from Hurco on site consists of two manual spark erosion machines and a 20-year-old Hawk CNC mill with manual tool change. The latter is still regularly used — along with similar milling equipment — for the production of simple items like electrode mounts.