Gosport-based

Kingsbury has been appointed to sell the products and services of

SLM Solutions Group AG, a German manufacturer of powder bed metal additive manufacturing (AM) machines, in the British and Irish markets with effect from 1 December — there are more than 600 systems in use world-wide.

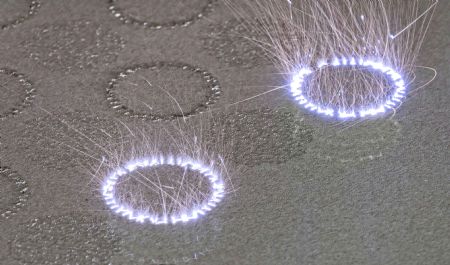

Headquartered in Lübeck and employing over 400 people, SLM Solutions is one of the inventors of selective laser melting (SLM) for 3-D printing components layer-by-layer from metal powder.

The process is used in research as well as for prototyping and increasingly for series production, predominantly in the aerospace, defence, automotive, energy, medical and tool making industries.

All SLM machine models produce parts accurately and efficiently from aluminium, titanium, nickel, cobalt, iron and copper alloys. Positioning the machines among the most advanced on the market are exclusive features such as bi-directional recoating, multi-laser overlap strategy and laminar gas flow.

Furthermore, the open architecture allows parameters to be modified without additional cost, so a user is able to customise the process to suit specific applications and to develop completely new alloys. Both abilities enable customers to differentiate themselves from competitors that use standard materials and parameter sets.

Until recently, machines ranged from a single-laser model with a build chamber of 125mm cube up to a quad laser version offering a 500 x 280 x 850mm build envelope.

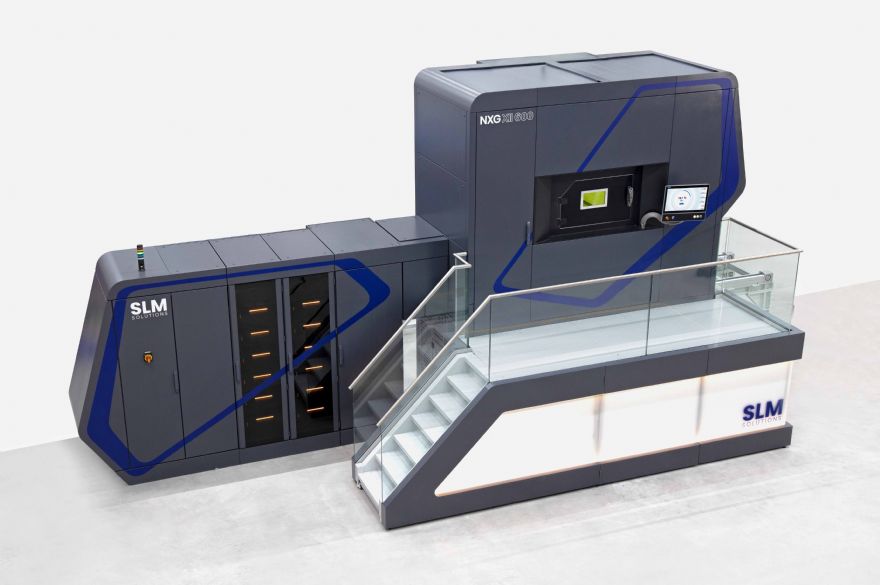

However, in November a major product launch extended the portfolio to include a 600mm cube machine with up to 12 lasers, which is by far the most productive selective laser melting system on the market.

The NXG XII 600 is up to 20-times faster than a standard single-laser machine and is equipped with innovative technical features such as a zoom function to achieve high productivity and at the same time high surface finish.

It is designed to be used for high-volume production as well as for printing large parts and opens up many new applications.

Kingsbury's managing director Richard Kingsbury said: ”We are delighted to be able to offer such a comprehensive range of production-oriented powder bed AM solutions. We see the technology, with the freedom of design that it brings to production, becoming increasingly important as we emerge from the Covid-19 pandemic, as it will enable manufacturing industry to innovate and become more competitive.”

David Wilckens, SLM Solutions Group AG regional sales manager, said: “The choice of Kingsbury to sell and service our systems was down to their already representing many well-known German machine tool manufacturers of high-value capital equipment, all of which see themselves as a technology leader, as we do.

“The match is made even better by the agent already being committed to AM technology and having an established department, with business development and applications engineering already in place.

“We and Kingsbury have a number of UK customers in common in various industries including medical, aerospace and defence, which will be excellent reference sites for prospective users. A dedicated demonstration machine will be installed in early 2021.”