Leamington Spa-based

Mills CNC Ltd, the exclusive distributor of Doosan machine tools in the UK and Ireland, recently supplied

Cutting Blue Ltd in Birmingham — a newly-created manufacturing arm of engineering consultancy and training specialist Cutting Blue Solutions Ltd — with a new Doosan vertical machining centre.

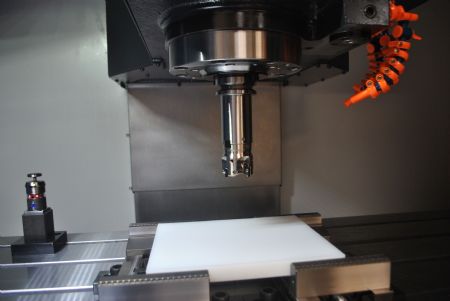

The large-capacity DNM 6700 was delivered and installed at the company’s 2,000ft

2 facility in Saltley in September, where it is currently being used to machine high-precision and high-value components in small batch sizes for customers in a variety of industry sectors, including motor-sport and general engineering.

Piotr Parobczy, Cutting Blue’s owner and managing director, started his working life as a machine tool setter. He then progressed to become a CAD/CAM programmer and more recently an engineering consultant, prior to setting up Cutting Blue in 2017.

Mr Parobczy said: “Although the company began as an engineering consultancy, even back then it was always my intention to create a manufacturing company when the time was right. That time turned out to be in the spring of this year, when the pandemic outbreak had a detrimental effect on the availability of contract work and this proved to be the catalyst I was waiting for.

Specialist high-precision milling services“Moreover, because creating a manufacturing company was a long-held ambition of mine I was not starting such an undertaking from scratch. Indeed, I had already done much of the ‘spadework’ and planning, having decided that the company would not be a ‘jack of all trades’ operation but one offering specialist high-precision milling services to customers typically in the high-end motor-sport, automotive and aerospace sectors.”

Mr Parobczy approached a number of machine tool manufacturers with his requirements. He said: “Several of those I approached sent literature but didn’t follow things up, but Mills CNC took time to understand the business, the type of work that would be undertaken and worked with me to identify the optimum machine tool solution.”

The DNM 6700 features an 18.5kW 12,000rev/min spindle, a 1,500 x 670mm table with a 1,300kg maximum load capacity, a 30-position automatic tool changer, roller LM guideways, and thermal error compensation.

The machine was also supplied with a Blum TC50 workpiece touch probe and a Blum ZX Speed IR tool-setting probe. Mr Parobczy concluded: “Although still early days, I am delighted with the DNM 6700 and am already looking at investing in a second Doosan machine.”