For finish turning of HRSA materials, Hertfordshire-based

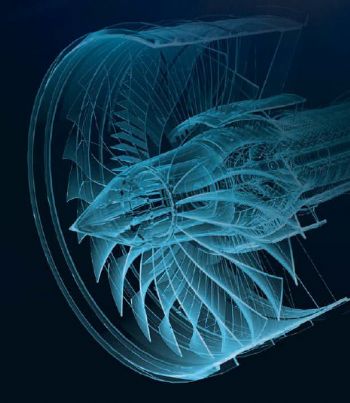

NTK Cutting Tools, a division of NGK Spark Plugs UK Ltd, has introduced a new range of inserts.

Suitable for machining HRSA materials at speeds up to 480m/min, the new NTK JP0 is the latest addition to the NTK range of Bidemics, a revolutionary material that can greatly improve productivity for aerospace manufacturers that are regularly cutting challenging materials.

Now, the newest evolution of this unique material technology from NTK demonstrates improved wear resistance and performance.

Capable of machining at cutting speeds up to 15-times faster than carbide and CBN alternatives, the new insert demonstrates exceptional wear resistance and consistency to deliver outstanding performance when machining heat-resistant superalloy materials.

The JP0 insert grade is suitable for running at cutting speeds from 180 to 480m/min with a feed rate of 0.05 to 0.2mm/rev and a depth of cut from 0.1 to 0.7mm.

Currently, NTK has introduced the new high-performance finish turning grade in three different designations, the CNGA, DNGA and VNGA geometries. The 4.76mm thick CNGA and DNGA inserts are available with a 0.4, 0.8 and a 1.2mm corner radius and an IC of 12.7mm.

The VNGA insert designation is available with a 0.4 and a 0.8mm corner radius with a 9.525mm IC; all three options demonstrate outstanding quality with the 0.04mm honed-edge preparation.

NTK recommends that when turning heat resistant super alloys and other challenging material types, manufacturers should utilise button inserts from the Bidemics, Whisker and SiAlON series for heavy-duty rough machining followed by the NTK SiAlON range for semi-finish passes with the exceptional new JP0 proving to be the insert grade of choice for finish machining with a constant depth of cut.