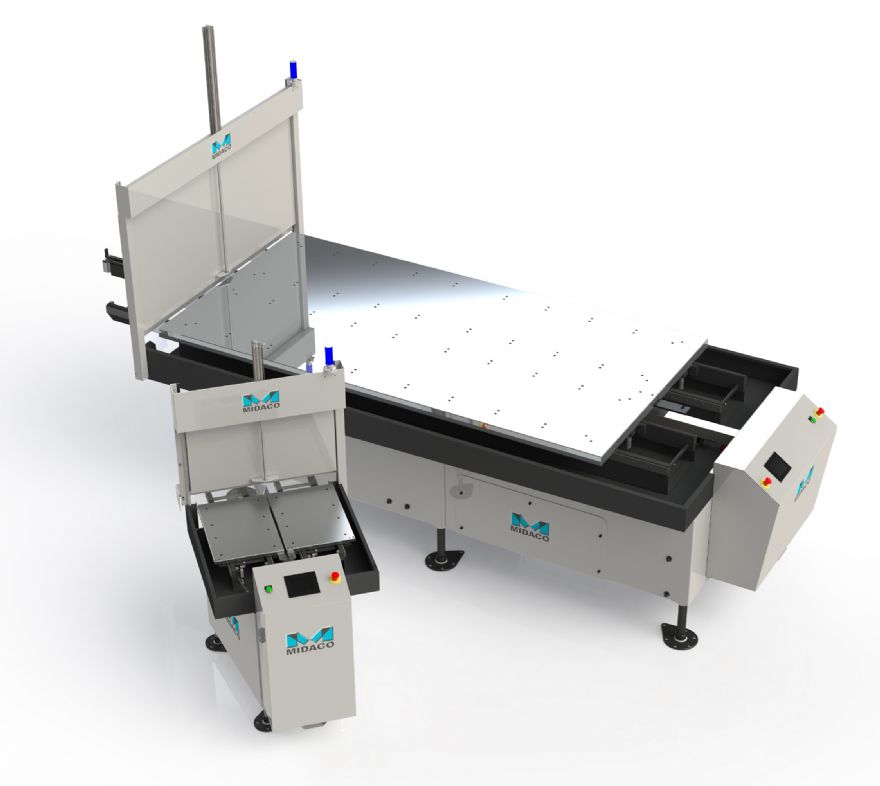

Automating a machining centre has never been so easy with the arrival of the new Midaco automatic pallet-changing system from Coventry-based

Hyfore Workholding Ltd, an automation, workholding and integration specialist. This ‘state of the art’ technology can be integrated into virtually any machining centre to improve up-time and spindle utilisation rates while reducing costs.

USA-based Midaco has decades of expertise in fast-change pallet systems and the latest system can be retrofitted to any new or existing machining centre, so operators can load, unload, inspect parts and set up jobs while an alternate pallet is in the machine and running.

It incorporates a PLC that is fully integrated with the machine tool, Mitsubishi control interface, a servo drive system, a receiver unit that mounts directly onto the machine tool table with hardened and ground location pins and a pallet system with precision ground rails to ensure long-term precision operation. Customers can also opt for the optional extra of a three-sided enclosure to maximise safety.

The benefit of this easy-to-integrate automation system is that it can be integrated with any machine tool, while heavy and large workpieces can be easily loaded outside the machine envelope and the pallets are interchangeable between machine tools.

Furthermore, the operator can load, unload, inspect parts and set up components while the alternate pallet is in the machine and the spindle is running. This maximises machine uptime and optimises the efficiency of the operator.

The automatic pallet system is available with several variants from the Series 16SD through the Series 120SD. The smallest pallet system has dimensions of 559 x 356mm with the largest pallet measuring 3,810 x 990mm with a pallet load capacity from 125 through to 3,636kg.

This expansive range of dimensions and load capacities makes the Midaco automatic pallet system suitable for everything from the smallest to the large component range. The most compact system in the series has a footprint of 894 x 1,143mm with the largest solution having a floor area of 2,350mm x 4,877mm.

The Midaco range also incorporates dual automatic systems, manual pallet systems, micro pallet systems and manual lift-off systems — so Hyfore Workholding can accommodate any requirement.