The

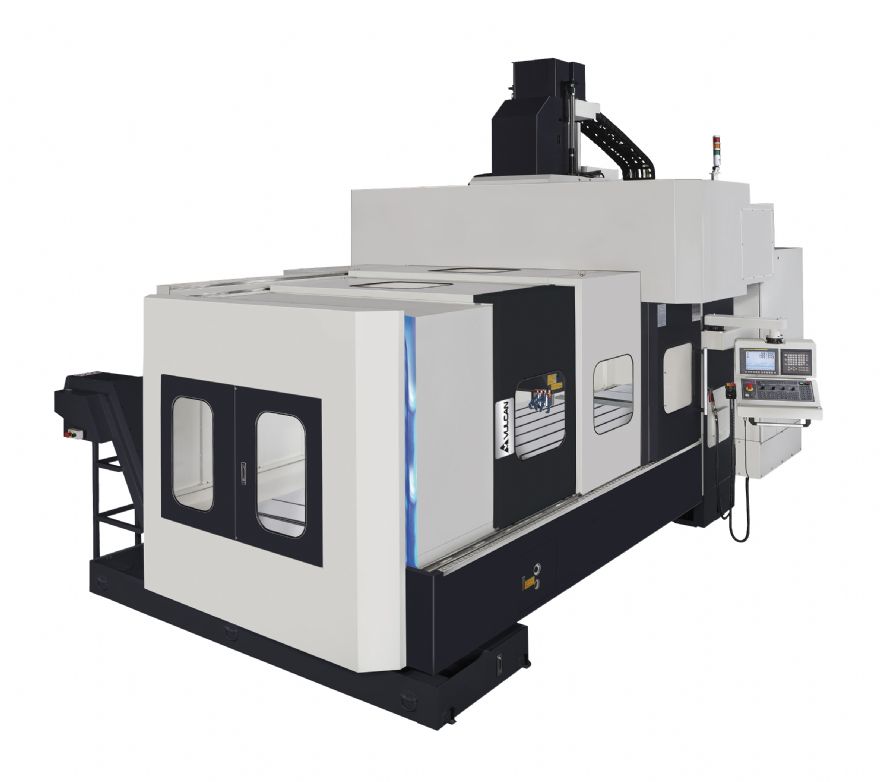

Engineering Technology Group (ETG) has introduced the new Vulcan Series of double-column machining centres for the highly productive machining of large components. The new range allows for the production of large complex components up to 10m in length and customers can opt for either a boxway or linear configuration.

The new boxway series is available in a number of variants that includes the DC Series 16/20B and the 23/26B and there are several dimensional alternatives. The smallest machine in the new 16/20B line-up is the DC2216/20B double column machining centre. The DC 16/20B Series has an X-axis of between 2.2m to 4.2m, a Z-axis of 800mm to 1m and a Y-axis of 1.6 to 2m depending upon the variant selected. The more compact of the new line-up, the DC2216/20B has an X-axis of 2.2m with a distance between the columns of 1.7m.

The DC2216/20B has a 2 x 1.4m (1.7m optional) table dimension with a maximum table load of 8,000kg, providing the end-user with a spacious work envelope with the capacity for large and heavy components. The spindle motor is available with a range of options that include an 18.5, 22, 26, 30 or a colossus 37kW motor with spindle speeds ranging from 6,000rev/min to 20,000rev/min depending upon the variant selected.

Regardless of whether the end-user opts for a high-speed or high-torque spindle variant, the spindle taper can be provided with the choice of BT50, ISO50 or CAT50 to meet the needs of the customer. Working in tandem with the spindle taper is a tooling carousel that can be selected with 24, 32, 40 or even 60 tool positions for maximum flexibility. The automatic tool change system can accommodate a maximum tool weight of 20kg and a length of 350mm with a maximum diameter of 125 or 245mm if the adjacent position is free.

The cast assembly of the Vulcan double column machines is equipped with lubricant recycling to keep the base clean, lubricant and coolant separation systems to prolong the service life of the coolant and a complete swarf management system to avoid damage to the guideways. The machines also incorporate a ‘box in box’ headstock structure design with square type ribs that efficiently reduce the weight of the headstock and also enhances the geometric and thermal stability of the machine, giving excellent rigidity and kinematics.

The robust construction of the DC2216/20B provides a foundation for precision as well as productivity and flexibility. This is demonstrated by the +/-0.005mm positional accuracy over 300mm of travel or an overall positional accuracy over the complete travel of the machine that is +/-0.015mm. This level of precision and repeatability is a credit to the design, kinematics and construction of the 20-tonne workhorse that has a compact floor area of 8.4 x 5.1m.