Wolverhampton-based

JTB Pressings Ltd has taken delivery of two new Fanuc-controlled CNC lathes from Leamington Spa-based

Mills CNC, the exclusive distributor of DN Solutions’ (formerly Doosan) and Zayer machine tools in the UK and Ireland.

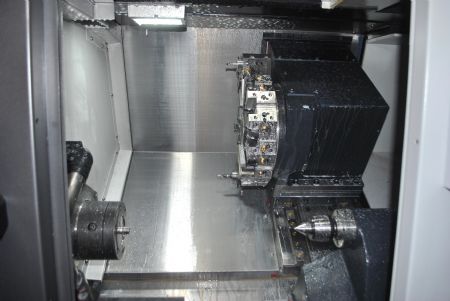

The machines, a 6in chuck 51mm bar capacity Lynx 2100LYSA and a similarly sized Lynx 2100, were installed at one of the company’s production facility in Willenhall in July and September, respectively.

Since their arrival both lathes have been put to work machining a range of small, precision-turned parts for global construction and agricultural equipment manufacturer JCB. These components, with their short cycle times and machined in high volumes, include six individual components, washers, bolts and bushes, made from a variety of materials that include steel, bronze and Nylon 6. They are being produced for a specific JCB Telehandler model’s door catch system which, after being machined, are then finished, powder-coated and assembled in-house.

Over 600 of these fully-assembled door catches are manufactured every week by JTB, a majority of which are despatched immediately to the customer’s production line and the remainder, including the assembly’s individual components, retained for spares and stock.

JTB’s decision to invest in the two DN Solutions’ lathes was made to help the company increase the range of manufacturing services it provides to existing customers, as well as spearheading a drive to secure business from a variety of new sectors.

Ivan Evans, JTB’s managing director, said: “We are always looking to improve, diversify and grow. As such, we regularly invest in advanced manufacturing technologies to increase our productivity, manufacturing flexibility and overall competitiveness.”

High-quality laser cut partsA recent example of JTB’s investment strategy in action saw the company, in 2018, acquire a ‘state of the art’, large capacity Nukon Eco 315 2kW laser cutting machine. He continued: “This machine has added another string to our bow. It has helped us grow the business enabling us to acquire a number of new customers looking for high-quality laser cut parts.”

For a number of years, JTB has provided a vertically-integrated, manufacturing service to customers, offering a ‘one stop shop’ which includes laser cutting, welding and fabrication, powder coating and assembly services.

Any turning requirements JTB had were previously sub-contracted out to local companies offering this specialism. However, to protect and strengthen its supply chain position with customers, help it increase productivity, improve process efficiencies, and control operational costs, JTB made the decision, back in 2021, to further expand the range of services it offered to customers, by developing its machine shop at its Willenhall facility.

Steve Lounds, JTB’s general manager, said: “We knew from experience, and from talking to customers and prospects, that there was a demand we could meet for machining high-quality, competitively-priced turned parts. We made the decision to meet this demand by creating a world-class, in-house sub-contract machining resource, focused on producing complex, high-precision small turned parts for customers.”

At the start of 2022, JTB began to put its plans into action. To narrow down the choice of potential CNC lathes for its new venture, JTB did its homework, investigated the market and attended

MACH 2022 in April.

Multi-tasking capabilitiesMr Evans continued: “We went to

MACH 2022 with an open mind and an outline technical specification for the lathe we required. We did consider sliding head as well as fixed head models, but ultimately decided on the Lynx 2100 LSYA from Mills CNC owing to its compact size, its proven reliability and its multi-tasking capabilities, which includes a sub-spindle, Y-axis and driven tooling. We also knew that DN Solutions’ machine tools, and Mills CNC, have good reputations in the market.”

The Lynx 2100LYSA was installed, with an integrated Hydrafeed bar feeder, at JTB’s 8,000ft

2 machine shop in Willenhall in July 2022 and, almost immediately, things began to change.

Mr Lounds continued: “A sudden, and sustained, increase in part volumes required by one of our major customers put our existing turning resource under pressure. It also resulted in the new Lynx lathe’s capacity becoming virtually swallowed up overnight, machining relatively simple components — not exactly what we intended when we made the investment.”

With no let up in demand from this major customer, JTB made the decision to invest in a second Lynx 2100 lathe. Partly funded by a business grant from Wolverhampton Council’s ‘AIM for Gold Grant and Growth Programme’, the second Lynx was delivered and installed at JTB’s machine shop in September 2022.

Mr Evans added: “Our second Lynx 2100 lathe is also integrated with a bar feeder – enabling us to achieve continuous production.”

With both Lynx lathes’ capacity taken up machining parts for just one customer, JTB has now made the decision to invest further.

Mr Lounds concluded: “To ‘free-up’ capacity on our Lynx machines we hope to invest in another two pre-owned Emi-Mec CNC lathes in the near future. These two-axis lathes will be able to handle the high volume of turned parts currently being machined on the Lynx lathes and, as a consequence, will enable us to fully exploit the Lynx lathes’ true potential and diversify our operations – as was originally intended.”

JTB is geared up for this eventuality having already recruited two experienced, and now CNC Academy trained operators to run its Lynx turning cells.