Japan-based

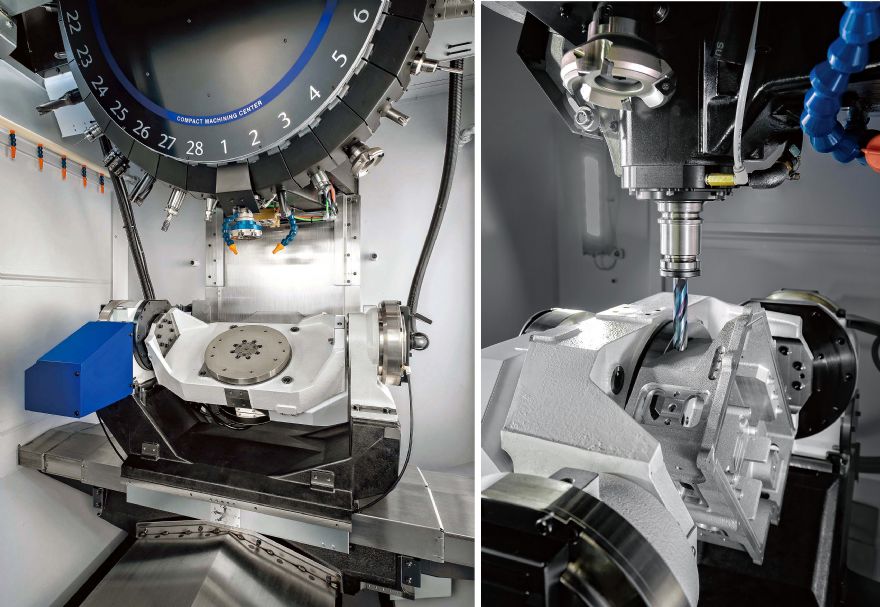

Brother, a 30-taper vertical machining centre (VMC) manufacturer, has introduced a new five-axis model with a swivelling rotary table — the Speedio U500Xd1. Despite having a nominal footprint of just 1.5 x 2m, it is capable of multi-face machining of components up to 500mm diameter x 270mm high and weighing up to 100kg.

Combined with a 28-position magazine for tools weighing up to 4kg and either a 10,000rev/min 18.9kW or 16,000rev/min 15kW spindle with a face-and-taper interface option, the production centre redefines machines in this class and is squarely aimed at competing with 40-taper machining centres — 30 or 70 bar through-tool coolant is available.

Sole sales and service agent in Britain and Ireland, Kenilworth-based

Whitehouse Machine Tools, points out that there is little competition to the machine on the market in terms of its sheer speed of operation. Rapid traverse is 50m/min in X: 500mm and Y: 400mm and even faster in Z: 300mm, which accelerates at 2.2g up to 56m/min. Chip-to-chip time is 1.3sec, or faster still if a 14- or 21-tool magazine is fitted. Cutter exchange and axis motions take place simultaneously to minimise cycle times.

Trunnion swivel (A-axis) at 50rev/min is a generous -30/+120deg and the table (C-axis) rotates at 75rev/min. Roller gear cam mechanisms drive both rotary axes and 0-90deg indexing times are 0.9sec and 1.2sec respectively. Clamping torques are high at 610 and 500Nm.

Lowering the power consumption of its machines has long been Brother's aim. For a start, the electricity and air used by a 30-taper machine is only about 20% of that required by a 40-taper machine. In addition to having a low inertia spindle and highly efficient spindle motor, the U500Xd1 is equipped with a power regeneration system that reuses energy generated when the spindle motor decelerates. Other energy saving measures include efficient filtration that limits the size of the pump needed, a low energy LED work light with automatic off function, automatic coolant off, standby mode and automatic power off.

Control of the machine is by Brother's latest CNC-D00 with 15in LCD touch panel, offering extended look-ahead and enhanced usability. The home screen displays the total and remaining cycle time, workpiece counter, remaining tool life and shortcut keys, without having to scroll through a menu. Support apps have been incorporated to give an overview of production and operational status, load monitoring, power consumption, tool set-up and adjustment, recovery support and cycle time optimisation.