The new DN Solutions’ TT 1800SY twin-turret, twin-spindle turning centre at Standish Engineering

The new DN Solutions’ TT 1800SY twin-turret, twin-spindle turning centre at Standish EngineeringLancashire-based

Standish Engineering Co (SEC), a family-owned engineering business celebrating its 75th anniversary this year, is a widely-respected and successful precision sub-contract specialist committed to continuous improvement. To maintain its competitive edge, the company regularly invests in advanced machine tools and ancillary technologies.

Since the 1990s, SEC has developed a strong relationship with Leamington Spa-based

Mills CNC and, over the last 30 years, has acquired a number of its Daewoo, Doosan and, most recently, DN Solutions machines — the most recent being a twin-pallet vertical machining centre (VMC) and a twin-turret, twin-spindle turning centre. These machines, like all the 15 CNC machines SEC has in its machine shop, are helping the company respond to, and meet, customers’ changing needs and requirements in a quick, efficient and cost-effective way.

The machines in question, a VC 430 and a TT 1800SY, were installed at the company’s 16,000ft

2 facility earlier this year, in May and October respectively, and are currently machining a range of high-precision, complex parts for customers in the rail, oil and gas, automotive, aerospace and food processing sectors.

Continued growth and successWhile all sectors are important to SEC it can be argued that business from the international rail and oil and gas sectors, and the company’s strong supply chain relationships with customers from both, have become increasingly significant to the company’s continuing growth and success. Indeed, it was these ‘critical infrastructure’ sectors, back in 2020/21, that proved to be more than instrumental in helping the company successfully find its way through the Covid-19 crisis.

However, despite their importance, a key consideration for the company has always been to minimise potential risk by not being overly reliant on one or two industrial sectors, so SEC is always looking to diversify its customer base and enter new markets. The company’s regular and planned investment in advanced, flexible and multi-tasking machine tools and ancillary technologies help it become more agile and more adaptable, and better able to implement and capitalise on its diversification strategies.

Standish Engineering’s new DN Solutions’ VC 430 twin-pallet vertical machining centre

Standish Engineering’s new DN Solutions’ VC 430 twin-pallet vertical machining centreComponents machined by SEC are characterised by their tight tied-up geometric tolerances and super-fine surface requirements, and they can be machined in small, medium or large batch sizes. Parts, both large and small, can be machined from solid billet and bar, as well as from castings and forgings, and materials machined by SEC also cover a wide spectrum and include aluminium, engineering plastics and mild and stainless steels, as well as numerous exotics and difficult-to-machine alloys such as Monel, Hastelloy, Inconels, Duplex and Super Duplex.

To improve its services to customers, SEC regularly monitors and benchmarks its performance against company KPIs to ensure that it consistently meets, and in many instances exceeds, the high standards it sets for itself regarding quality, efficiency, value and customer satisfaction.

A company-wide mantra that permeates throughout the whole organisation is that the “customer is king”. This philosophy provides a clear, unequivocal focus that has resulted in improved customer loyalty, high retention rates and repeat business from existing customers, as well as the ability to win new business.

Nick Kindon, SEC’s managing director, said: “We are constantly adapting the business to meet customers’ needs more effectively, and always strive to be the best we can be.” Nowhere is this more evident than in the company’s well-resourced machine shop where frequent and planned investment in new advanced machine tools, inspection and laser marking equipment, help the company improve its machining capacity, its production capabilities and its machining processes too. The new high-productivity and flexible VC 430 installed in May 2024 replaced an older (Daewoo) ACE vertical machining centre that was acquired by SEC in the late 1990s.

Mr Kindon continued: “Although the ACE machine has served us well over the years, it wasn’t as reliable as it used to be. Rather than jeopardise our machining performance with a potentially unreliable machine, and to avoid unforeseen production bottlenecks and scheduling issues caused by downtime, we decided to update it. Initially, we were looking to replace the machine with a five-axis machining centre but then realised that continuing with a new, next-generation twin-pallet VMC would be the best solution.”

Rigid designSEC approached Mills CNC to discuss its requirements and were introduced to the DN Solutions’ VC 430 machine series which has a twin-pallet configuration enabling continuous machining of large and/or multiple smaller parts in a single setup. It has a rigid design and build and is equipped with a powerful, 18.5kW 10,000rev/min 167.6N-m high-torque spindle, two automatic pallets (712mm x 490mm x 2), each with a 300kg maximum load, up to 40m/min rapids on its X , Y and Z axes, roller guideways and a fast 30-postion automatic tool changer (ATC). The one supplied to SEC also featured a 20bar through-spindle coolant capability, and a MH500 chip conveyor.

The interior of the new DN Solutions’ VC 430 twin-pallet vertical machining centre at Standish Engineering

The interior of the new DN Solutions’ VC 430 twin-pallet vertical machining centre at Standish EngineeringMr Kindon said: “The new VC 430 has slotted in seamlessly and as expected, is making a significant contribution to our productivity and performance. We are looking to replace our last two remaining ACE twin-pallet VMCs in the near future, and it looks likely that we will be approaching Mills CNC in the next few months to discuss trading them in for two more VC 430 machines.”

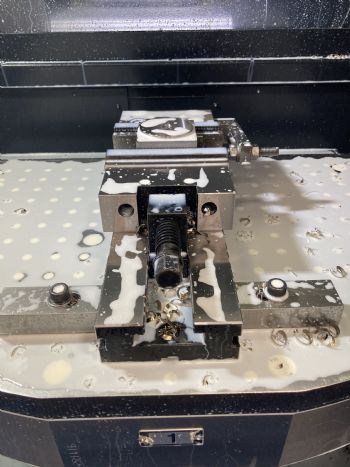

Meanwhile, a new, compact TT 1800SY, installed at SEC’s machine shop in October 2024, has replaced an older TT machine that was acquired by the company in 2007. The 8in chuck/65mm bar capacity TT 1800SY is a productivity powerhouse designed for fast small-parts processing and features 22kW 5,000rev/min twin-opposing spindles, an upper and a lower turret, both 24-position, with 5,000rev/min driven tooling capabilities, and a +/-50mm Y axis. The particular machine supplied to SEC also included a MF500 swarf conveyor, a CRS66 collet chuck and, to ensure continuous production, a HydraFeed MultiFeed 65 bar loader.

Mr Kindon added: “Our first TT 1800SY served us well over the last 17 years, and could operate as a self-contained, automated manufacturing cell. We relied on its accuracy, flexibility and speed, so when the machine needed to be upgraded it was natural that we approached Mills CNC to talk about the new, next generation TT1800SY series. Our new machine has only just been installed, but we have very high expectations regarding its performance.”

He concluded: “We like Mills CNC, the company understands our business and is approachable and transparent. The depth and breadth of its machine tool portfolio is second-to-none, and the fact that it keeps many models in stock at its Leamington Spa facility, ensures their quick delivery and installation. This, in addition to Mills CNC’s technical and logistical expertise combined with its responsive after-sales service and support operations, puts it in the box seat whenever we are looking to invest in new machines.”