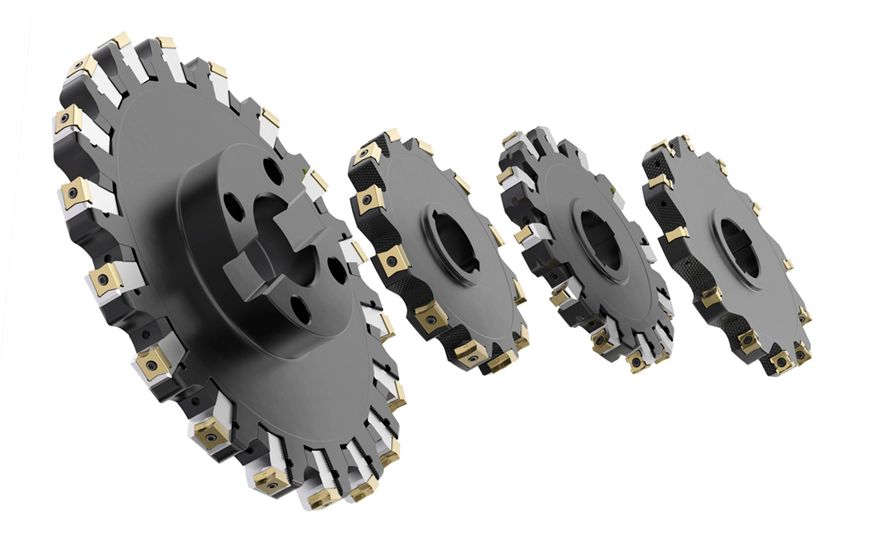

New Seco 335.98 Disc Milling Cutter System 335.98 with steering knuckle

New Seco 335.98 Disc Milling Cutter System 335.98 with steering knuckleThe new

Seco 335.98 Disc Milling Cutter system achieves the lowest cost per part in half-side and face disc milling operations, making it a first choice for mass production environments. The system’s combination of cutter body and insert geometries further enhances performance through a strong interface, free-cutting design and minimisation of cutting forces. Seco 335.98 disc milling cutters use dedicated inserts with eight usable cutting edges. The unique geometries of the inserts yield up to 60% longer life in left-hand and right-hand side disc milling operations.

Seco product manager Benjamin Michelet said: “The 335.98 disc milling cutter achieves the best possible performance and excels in high-volume production applications, especially those involving components with right-hand and left-hand side milling operations. Not only will manufacturers, such as those in the automotive industry, increase their productivity, but they will also significantly reduce their tooling costs through decreased insert consumption.“

Optional insert cassettesSeco 335.98 disc milling cutter bodies are also available with optional insert cassettes. The cassettes increase flexibility through quick, easy insert changes, and they significantly reduce repair costs if a pocket is damaged, as only the cassette needs replacing.

The Seco 335.98 disc milling system offers a strong, reliable interface between cutter body and insert to maximise stability. Furthermore, this unique interface simplifies insert setup and indexing by preventing mounting mistakes. The free-cutting design of the inserts optimises chip flow to avoid potential jams, while also minimising cutting forces to eliminate vibration and increase part quality.

Inserts are available in two standard sizes with a broad range of grade and corner radii options. This enables the flexibility to apply the system to a broad range of material types and applications. For high-volume applications, the Seco custom tools department provides on-demand customisation to further optimise performance.