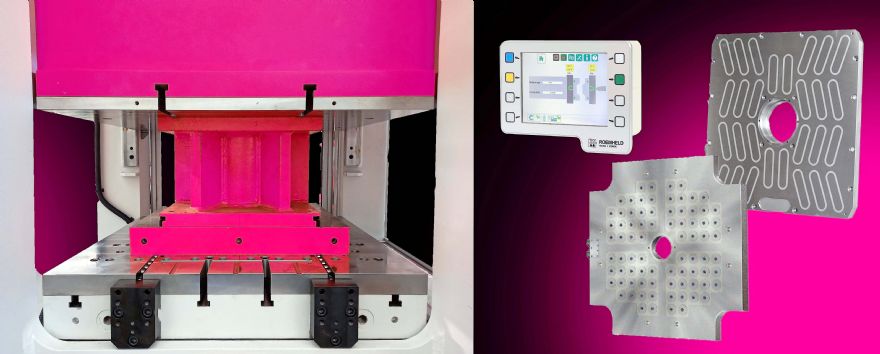

The new R-MAG-M magnetic clamping system for sheet metal forming has integrated clamping force display and interchangeable magnetic polesRoemheld

The new R-MAG-M magnetic clamping system for sheet metal forming has integrated clamping force display and interchangeable magnetic polesRoemheld will be presenting several innovations at

Blechexpo (Stand 8505, Hall 8), taking place 21-24 October in Stuttgart, for helping manufacturers to reduce set-up times in sheet-metal forming and to increase operational reliability. One will be R-MAG-M, the company’s first magnetic clamping system for sheet metal forming, offering interchangeable magnetic poles and display of the clamping force on an 8in screen, both features that were requested by numerous customers.

Within seconds, the electro-permanent magnetic system is able to secure dies of various sizes and geometries automatically and without distortion, ensuring secure clamping even in the event of a power failure. Temperature sensors, position switches and flux measurement sensors monitor the system during sheet metal forming. The replaceable magnetic poles simplify maintenance and minimise downtime, as defective poles can be replaced on site.

A new, electrically-operated variant of the RW 1000 series of die changing carts for tool loads up to 1,000kg will be on display. Unlike its manually driven counterparts, the RW 1000 ELMO has electrically actuated lift and drive. Available also is a B version, with an additional integrated docking strip at the front, making it easier to move the dies onto the machine table.

For particularly heavy tools, Roemheld is presenting the new RWT die-changing cart at the trade fair. The electric vehicle (EV) with radio remote control for ergonomic die handling of loads up to 4,000kg is a fully integrated transport solution. It combines a powerful drive with an electro-hydraulic lifting platform, an integrated push-pull system, hydraulic ball bars and docking devices. This enables safe transport, effortless automatic extension and retraction, and precise positioning of heavy dies. A radio remote control ensures flexibility and ergonomics.

Maximum stability and durabilityOn the stand will be a Flexline-R quick-acting clamping system for press dies, based on the proven Flexline models and optimised for heavy loads. It is particularly well-suited to automated press lines on which die changes are frequent. At its core is a welded stainless steel pull-push chain that offers maximum stability and durability. Reinforced brackets, stainless steel components and an emergency release on the motor enhance operational safety. Precise sensors monitor the position of the clamping element and, optionally, the end position of the chain.

Flexline R is available with two adjustment ranges and with various hollow piston cylinders offering clamping forces of up to 104kN. The compact design, low weight and use of low-maintenance modules facilitate installation and servicing. Due to the inclusion of an integrated line for energy supply and signal transmission, a separate guide is not required.

There is also a new Green Edition variant with 24 volt DC power supply, which is used instead of the 120 or 400 volt AC motor in the original version. The safe, extra-low voltage simplifies project planning and makes the element compatible with almost any press worldwide. It eliminates the need for additional voltage conversion or adaptation to country-specific power grids. The design is aimed both at manufacturers who are equipping new press systems and at users who want to retrofit existing presses.