Alcester-based

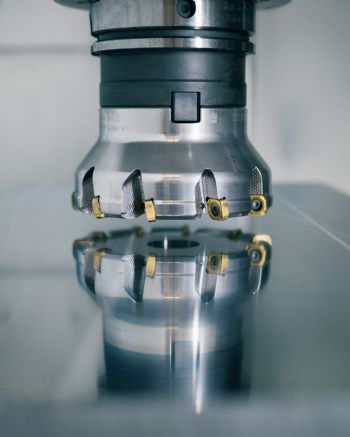

Seco Tools (UK) Ltd has unveiled its latest innovation in high-precision surface finishing with the launch of the .38 Finishing Face Mill system, a development that promises to simplify and elevate finishing operations across the industry. The new system is designed to offer both flexibility and ease-of-use, with three distinct cutter variants tailored to a range of finishing requirements.

The .38 Finishing Face Mill/SNFX1204 system comprises fixed pocket, hybrid, and adjustable cutters, each engineered to deliver a specific balance of control and performance. For those seeking straightforward, setup-free operation, the Fixed Pocket Cutter (R220.38-….-SN-..SA) stands out. Its tilted screw design ensures perfect insert self-centring and delivers run-out accuracy between 4 and 15µm, making it a cost-efficient solution that reduces the risk of operator error and minimises training requirements.

For users who require a blend of flexibility and simplicity, the Hybrid Cutter (R220.38-….-SN-..CSA) combines fixed and adjustable cassette pockets. By default, it operates as a fixed pocket tool, but the cassette inserts act as dedicated wipers to enhance surface finish. Adjustment is possible, but not necessary, allowing users to benefit from flexibility without added complexity.

At the top end of the spectrum, the Adjustable Cutter (R220.38-….-SN-..HSA) offers fine-tuning capabilities that achieve run-out as low as 0–2µm, making it the tool of choice for applications where surface perfection is paramount. The system also features two insert types: one with an 88deg lead angle for near-wall machining, and another with a 27deg lead angle for high-feed, open-surface work. This dual-insert approach enables users to tackle a wide range of finishing challenges while keeping operations streamlined and cost-effective.

Tobias Jakobi, face milling project manager at Seco, said: “With the .38 Finishing Face Mill system, we’ve focused on making high-performance finishing both easy and dependable. Ease of handling is essential in finishing operations, and this solution gives users the flexibility to meet varying demands — often with just one system where two might have been needed before.”

Seco’s .38 Finishing Face Mill system is set to make a significant impact for manufacturers seeking to combine precision, efficiency, and simplicity in their finishing operations.