Fritz Studer AG’s

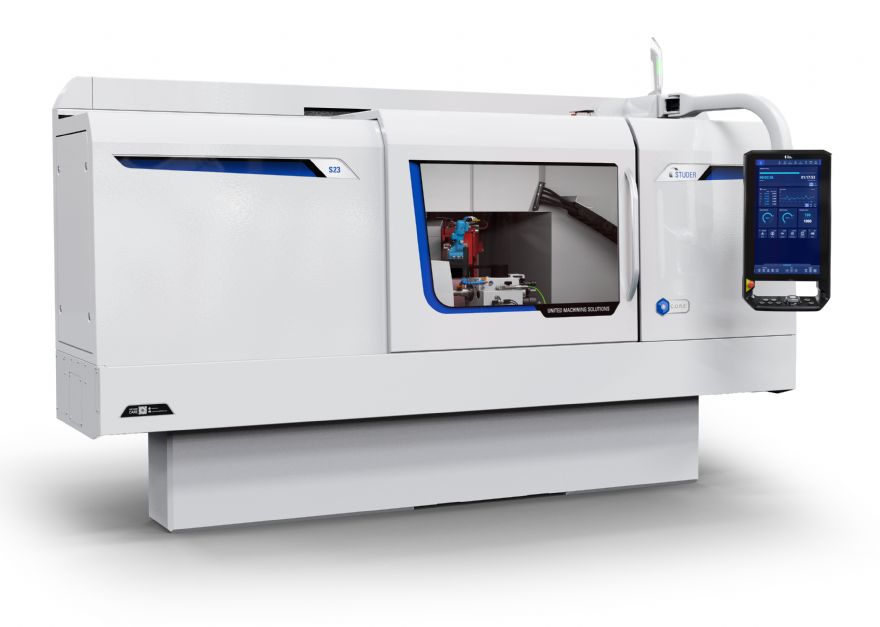

Fritz Studer AG’s new S23 CNC universal cylindrical grinding machine made its global debut at

EMO Hannover 2025 last week. Designed for both entry-level and premium applications, the S23 combines compact design with high-end grinding performance. CEO Sandro Bottazzo said: “Thanks to its high-quality features, precision, and flexibility, the S23 complements our portfolio in the entry-level and premium segments.”

Equipped with the latest C.O.R.E. hardware and software, the S23 features an automatic B-axis with 1deg Hirth coupling for up to three grinding tools, frequency-controlled motor spindles or belt drives, and a Granitan machine base for optimal thermal and vibration stability. The wheelhead configuration allows multiple grinding operations in a single clamping, enhancing efficiency for complex geometries.

Advanced functions such as contact detection, semi-automatic wheel balancing, and optional in-process measurement ensure consistent quality. Sales manager Rolf Grossenbacher said: “The S23 is ideal for production in the tool and die, automotive and supplier, aerospace, and medical technology industries.”

The machine supports a wide range of configurations, including a C-axis for thread and out-of-round grinding and an optional swiveling table. With intuitive operation via the C.O.R.E. touch panel and StuderWIN software, plus fast changeovers using QuickSet, the S23 is also automation-ready with standardised interfaces for easyLoad and insertLoad.

Mr Bottazzo concluded: “This makes the S23 a high-precision universal cylindrical grinding machine with an excellent price-performance ratio.”