Hydraulic composite forming pressRhodes Interform

Hydraulic composite forming pressRhodes Interform, one of the UK’s leading metalforming machinery manufacturers, has won a multi-million-pound contract to design and build three custom hydraulic presses for the aerospace sector. The presses will be used in the production of lightweight aero structures.

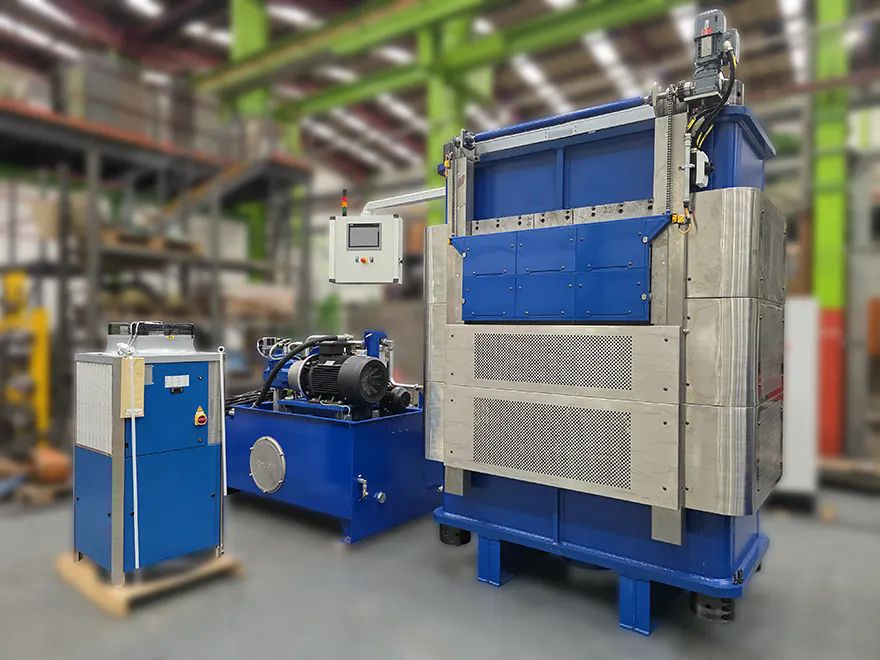

The order comprises two 180-tonne presses and one 500-tonne press, all designed to bond multi-layered composite sheets into a single formed component. Each machine is a four-column, hot platen press with electrically heated platens capable of operating at temperatures up to 220°C. The presses feature PLC control and incorporate advanced systems such as integrated structure cooling, fume extraction, and precise speed, tonnage, and temperature regulation.

The design, manufacture, and commissioning of the presses were managed by Rhodes Interform’s engineering team at its Wakefield facility. The process included full factory testing before reassembly and final trials at the customer’s site.

Mark Ridgway, CEO of Group Rhodes, said: “This was a very prestigious contract, which involved a close working partnership between our design, technical, and production teams as well as the client, to meet their specific requirements. We have extensive experience in the aerospace sector, and the project is a testament to our expertise in the design and manufacture of bespoke presses to meet specialist composite forming and metal forming applications.”

Rhodes Interform is a division of Group Rhodes, a company with over 200 years of engineering heritage and decades of experience supplying turnkey solutions to the aerospace industry. The group also holds patents in Europe and China for its Superplastic Forming (SPF) and Diffusion Bonding (DB) technology, which is widely used for producing large, complex components and supports lightweighting initiatives in aerospace and automotive applications.