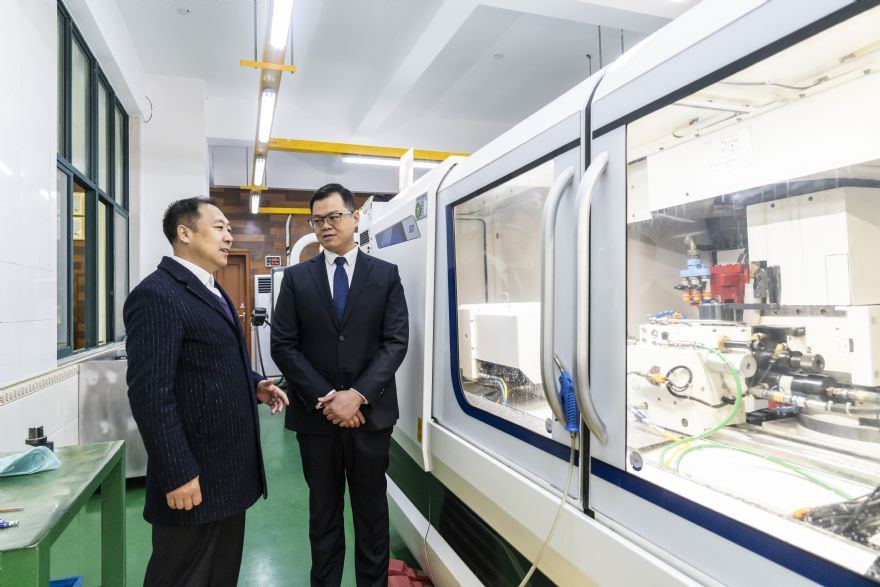

Evermore’s general manager Barry Liao (left), with Wu Kui, sales manager and senior sales technology support at United Grinding China

Evermore’s general manager Barry Liao (left), with Wu Kui, sales manager and senior sales technology support at United Grinding ChinaIn the north of Jiaxing, 62 miles southwest from Shanghai, Evermore has been producing high-quality precision machine components for more than two decades for demanding sectors such as automotive and medical technology, and thanks to precision cylindrical grinding machines supplied Swiss machine tool manufacturer

Fritz Studer AG, the Chinese manufacturer has enhanced both production efficiencies and product quality.

Evermore’s operations specialist Mr Chen (pictured below), who has notched up over 18 years’ experience, oversees the production of the company’s C6 type tool holders. He said: “Our Studer S31 cylindrical grinding machine works reliably, has a very high machining accuracy, and the material wastage is low.”

Meanwhile, in Evermore’s nearby showroom, polished workpieces pay testament to the company’s expertise — on display are conical shapes of high-alloy steel, toolholders, and chucks for drills and other tools. Barry Liao, Evermore’s general manager, said: “Our customers appreciate the uncompromising quality of our products, both in terms of geometry and surface finish.”

Over more than two decades, the company has earned a reputation for precision components across industries ranging from automotive and electronics to hydraulics and medical technology. This success story began in 2000 when Liao’s father founded the Jiaxing subsidiary. Initially focused on CNC chucks, tool systems, and tool holders, Evermore steadily expanded its portfolio, investing in advanced technologies and optimised processes. Mr Liao added: “Our success is also inseparably linked to the close cooperation we have with Studer.”

Extensive expertiseWu Kui, a sales manager and senior sales technology support at

United Grinding China, who has supported Evermore for years, said: “With the extensive expertise of our engineers, we were able to competently advise Evermore from the beginning on which machines and configurations are best suited for its individual products and production processes, and I personally trained some employees here on Studer machines.”

His guidance helped Evermore implement multiple grinding functions — internal and external contours, non-round geometries, and end faces — all in a single machine, significantly boosting efficiency.

Today, Evermore’s 14,000m

2 production site employs 230 people and houses several Studer cylindrical grinding machines. Two S131 CNC universal internal cylindrical grinding machines handle high-precision internal bores in polygon shaft components and the other grinds internal threads for miniature adjustment screws. Compact yet powerful, the S131 features innovations such as the StuderGuide guideway system, linear motor axis drives, and a fast direct-drive grinding spindle turret.

Meanwhile, an S31 grinds precise external diameters of polygon shaft components, thanks to its modular design and swivelling wheelhead with a B-axis resolution of 0.00005deg, the machine is very flexible and is ideal for small to medium-size workpieces with a maximum weight of up to 150kg. Furthermore, its Granitan S103 machine bed ensures stability and repeatable surface quality. Completing the line-up, a Studer KC33 delivers precision external threads for the adjustment screws. This economical STUDER universal cylindrical grinding machine is manufactured in China and is appreciated for its versatility, precision, and reliability.

Dependable process reliabilityMr Liao explained: “We chose Studer machines because they enable precise machining with dependable process reliability, and produce virtually no scrap. Faster setup and retooling, simple operation, and automation options have further reduced costs. In addition to this, the quality of our products is at a higher level thanks to Studer. All these features have significantly increased our competitiveness.”

Mr Wu said: “For us, it is enormously important to support our customers as quickly and competently as possible. Anyone who purchases a Studer machine also receives excellent customer care.” Mr Liao agreed, recalling a time when urgent technical advice from Studer optimised a critical production process.

Looking ahead, Mr Liao sees collaboration as more vital than ever. Customers in the automotive, electronics, and medical sectors demand increasingly precise components made from challenging materials. He said: “I think artificial intelligence (AI) will become even more important, for example for real-time adjustment of grinding parameters or for automatic generation of the optimal machining path.’

Mr Wu concluded: “That is also interesting for our specialists in development.” Studer is already busy paving the way with digital processing and analysis technologies that enable rapid product line changes and strengthen competitiveness.”