Mapal

Mapal is expanding its NeoMill milling cutter product range to encompass the semi-finishing and finishing of steel and cast-iron materials as well as the roughing of aluminium components.

First seen at

EMO Hannover 2025, Mapal expanded the NeoMill milling programme with three new series — NeoMill 16 Finish, NeoMill 16 Face, and NeoMill Alu Rough — specifically tailored to the requirements of series production. All three milling cutter series stand for high cost-effectiveness and process reliability as well as sustainable manufacturing and seamlessly integrate into the existing portfolio.

The NeoMill-16-Finish was developed for finishing tasks where requirements on surface finish and dimensional accuracy are high. With the combination of the pre-machining insert ONMU05 with 16 cutting edges and the OFGW07indexable insert with eight cutting edges for finishing, Mapal offers a unique system with complete process reliability. The face milling cutters are available in standard sizes in the diameter range from 63 to 200mm and enable easy setting of the finishing inserts. This makes surface qualities of up to Rz 4µm possible.

The NeoMill-16-Face is joining the portfolio of tools for pre-machining. Cost-effectiveness is in focus here, too — the ONMU05 plate with 16 cutting edges ensures low costs per part and stable machining. The tools are available in diameters from 32 to 100mm and are particularly suitable for series production of cast-iron and steel components with low stock removals (up to 2mm).

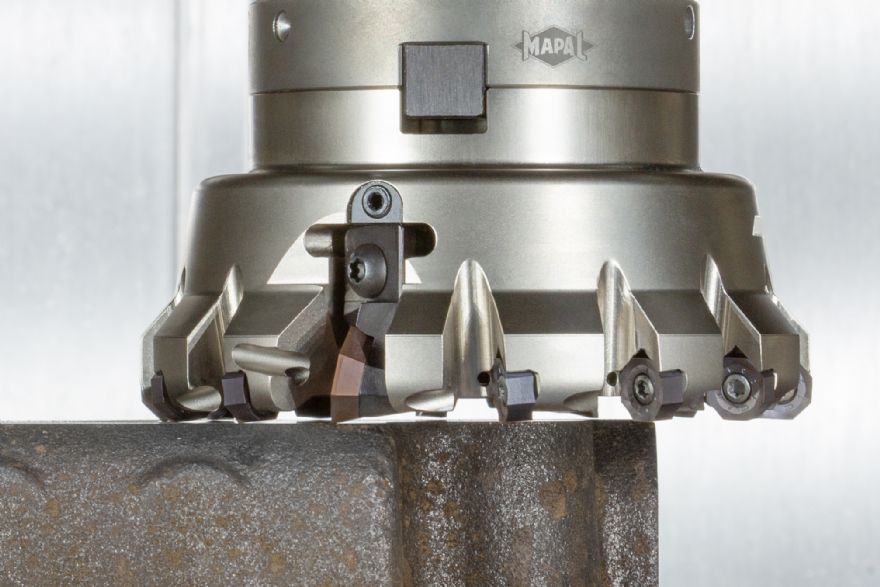

Meanwhile, with the shoulder milling cutter and shell end face milling cutter NeoMill-Alu-Rough, Mapal offers an innovative solution for roughing cast aluminium components in the automotive, aerospace and mechanical engineering industries. In the standard range, milling cutters with a single row of inserts are available at diameters from 50-160mm.

The NeoMill-Alu-Rough is available with multiple rows of inserts as a shell end face milling cutter with diameters of 63, 80 and 100mm. Customer-specific tool solutions can also be configured. The combination of large chip spaces, tangential indexable inserts and a wide selection of cutting materials (PCD, coated or uncoated carbide, CVD diamond) ensure reliable chip removal and high stability – even with large chip volumes.

With the NeoMill programme, Mapal has successfully served the milling tool market for series production for many years. With the newly developed NeoMill-16-Finish, NeoMill-16-Face and NeoMill-Alu-Rough series, the tool specialist is emphasising its expertise in the semi-finishing and finishing of steel and cast-iron materials and the roughing of aluminium.