Lantek

Lantek has strengthened its position in the global sheet‑metal technology sector through a new collaboration with Canadian cutting-systems specialist

Machitech. The agreement will see Lantek’s software integrated directly into Machitech’s high‑performance laser, plasma and oxy‑fuel cutting machines as the company continues its international expansion, particularly across North America and Europe.

Under the arrangement, Machitech’s Fiber Prime S laser cutting models will incorporate Lantek Expert Cut, while its Fiber Tube XL systems will be equipped with Lantek Flex3D Tubes. The partnership aligns with Lantek’s strategy of working closely with machine builders that place a premium on engineering standards and technical reliability. Juan José Colas Lastra, chief of sales and marketing officer at Lantek, said: “This collaboration clearly reflects the type of growth we are driving at Lantek. Working with a Canadian manufacturer like Machitech, with a solid technological foundation and a strong industrial focus, reinforces our international expansion strategy alongside partners that value engineering, reliability and technical expertise.”

Quebec-based Machitech has built its reputation on custom-built cutting systems, notably in high-power plasma and oxy‑fuel technologies designed for demanding industrial environments. The company has broadened its scope in recent years to include equipment for steelwork, structural profiles and tube processing, catering to manufacturers handling complex, high-value production. The Fiber Prime S range covers power levels from 12 to 60kW and includes bevel‑cutting capability for heavy‑gauge steel applications. The XL variant, developed for long‑format parts, features touchscreen controls and remote-management functions suited to rigorous production settings.

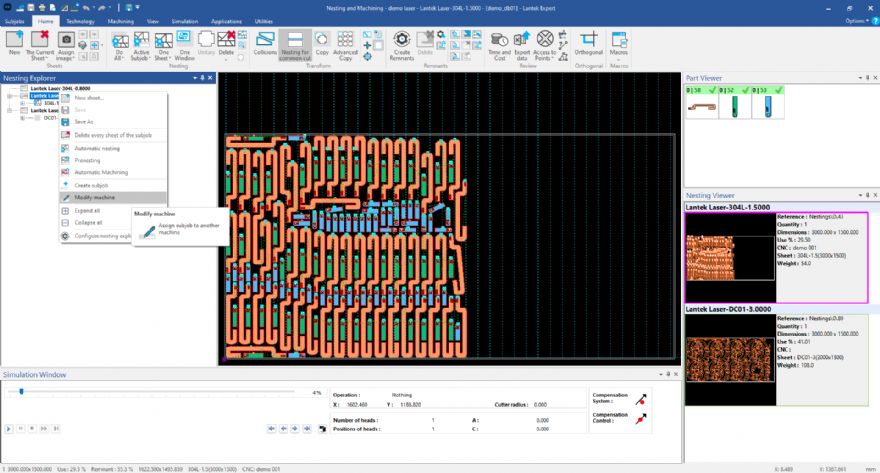

As part of its focus on performance and usability, Machitech has opted to integrate Lantek’s fully featured CAD/CAM environment to ensure optimal operation from the outset. Lantek Expert Cut provides advanced 2D nesting, automated cutting‑path generation and direct manipulation of 3D geometries via the Assembly 2 Nest importer, all within a unified workspace.

For tube‑processing applications, the Fiber Tube XL uses Lantek Flex3D Tubes, which supports round and square tubes, HSS profiles and small beams up to 40ft in length. The software enables design, nesting and machining directly on tubular components and offers SAT and IGES file import, together with simulation functions and real‑time adjustment tools to improve cut quality and protect machine components.

Simon Croteau, vice president of marketing at Machitech, said: “Our customers were looking for a proven software solution that could integrate naturally with their processes and the machines they already operate. Lantek is a well‑established reference in the industry and fits perfectly with our approach to manufacturing.”

Through this agreement, Lantek continues to extend its international footprint, reinforcing a strategy that centres on partnerships with technology manufacturers known for their engineering pedigree and commitment to advanced solutions for sheet metal, tube and structural steel processing.