With a new multi-channel condition monitoring system (CMS) specifically designed for machine tools, Sutton Coldfield-based Schaeffler (UK) Ltd (

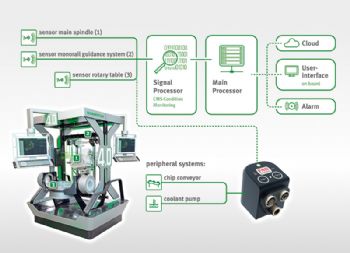

www.schaeffler.co.uk) is pursuing two objectives: condition monitoring and condition predictions for key components found on machine tools using a single CMS; and the flexible integration of sensors from different manufacturers into the CMS.

Schaeffler presented a functional prototype of the multi-channel CMS for machine tools at the EMO exhibition in Hanover.

In-house systems such as piezo-electric vibration sensors can be connected to the CMS, while piezo-electric vibration, force and pressure sensors from other manufacturers can also be integrated via an IEPE (Integrated Electronics Piezo Electric) interface.

The current prototype has six measurement channels and is designed so that, for example, the electronic monitoring of the lubrication conditions in linear recirculating roller bearing and guideway assemblies can also be integrated in the future.

As a result of connection to the Schaeffler Cloud, all digital services offered by the company for monitoring and detecting damage to rolling bearings are already available in the prototype CMS.

At a local level, the multi-channel CMS facilitates the monitoring of FAG rolling bearings based on an integrated bearing catalogue, as well as bearings from other manufacturers (after entering specific bearing data).

A completely new development is the option to interpret vibration signals from ballscrew drives. The beta version of the software module, which is currently in testing, will be available to customers shortly.

Schaeffler’s prototype for machine tools is intended primarily to provide pilot customers with the CMS functions at a development stage close to volume production status.

The prototype is currently being tested in initial pilot projects using various types of machine tools, including in-house production machines and those of selected partners.