Coventry-based NUM (UK) Ltd (

www.num.com) has unveiled a major upgrade to its Numroto tool-grinding software.

Offering numerous additional features and enhancements, Version 4.0 is designed to increase the productivity of tool and cutter grinders without the need for additional hardware.

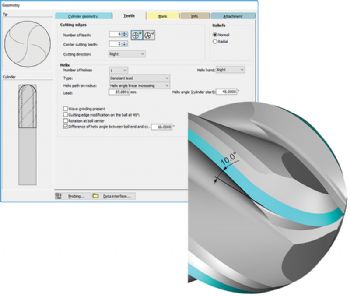

A notable enhancement sees ball-nose and corner radius facilities in Numroto allow the programming of a helix step on end mills. For the first time, it is possible to program different helix angles for the end of the radius and the beginning of the cylindrical section.

A further upgrade concerns Numroto Draw, which automatically processes the geometry data used for grinding a tool to generate a basic drawing.

Many Numroto users choose to provide this drawing with the finished ground tool, to show their compliance to standards; the latest software release extends this capability by automatically displaying the geometry of the grinding wheels and grinding-wheel packages needed to make the tool in the drawing.

Furthermore, all the important dimensions are added automatically to the grinding wheels.

The time-saving benefits of this approach are said to be considerable: a grinding-wheel assembly drawing can be printed out for the machine operator to help speed set-up without having to involve the design department, which is especially advantageous for companies handling numerous small production runs.

The 3-D simulation facilities of Numroto 4.0 have also been enhanced.

For instance, coolant holes in the 3-D blank are displayed automatically, and users can now add DXF comparison profiles.

Furthermore, there is a new measurement mode that provides comparator functionality, while the programmed feed rate can now be displayed during 3-D simulations.

A new feature that will appeal to users of high-end machine tools is support for adaptive grinding.

By continuously monitoring the dynamic performance of the grinding spindle, the software enables the feed rate to be optimised automatically.