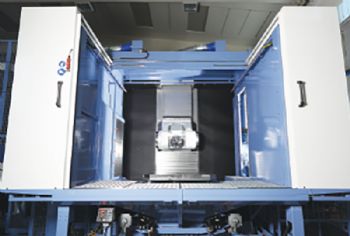

Machining centre and flexible manufacturing system manufacturer MCM — based in Piacenza, Italy — has further developed its TANK-series of four- and five-axis machining centres with the development of its TANK.G series.

These machines offer customers the flexibility of a wide choice of axis travels, along with multiple options for pallet size, tool changer and spindles.

There are also various head options, including horizontal and tilting heads with worm-screw or torque motor drives.

Sold in the UK and Ireland by Erith-based RK International Machine Tools Ltd (

www.rk-int.com), MCM machines are used in a variety of industry sectors, including aerospace, energy, oil and gas and general engineering.

Pallet sizes range from 800 x 1,000mm to 1,250 x 1,600mm; and on the MT range of mill/turn models, a rotary pallet capable of 200rev/min is available.

TANK.G machines are at the larger end of MCM’s machine range, with work envelopes from 1,600 x 1,500 x 1,850/2,000mm up to 3,000 x 2,500 x 2,500mm.

Moreover, axis travels up to 50m/min and acceleration rates of 3g are possible, with a repeatability of 3µm on linear axes and 3arc-sec on rotary axes.

The rotary-axis table can also be used for turning operations at rotational speeds up to 500rev/min; and, depending on the machine specification, loads up to 5,000kg can be accommodated.

The spindle options with TANK.G machines offer speeds from 6,000 to 30,000rev/min, with powers up to 130kW and torques up to 1,300Nm.

Further versatility is provided by TANK.G’s tool-change system, which features a modular rack tool system that holds 80 tools as standard but can be configured to hold up to 999 tools (weighing up to 35kg).

Tool-change time are between 2.5 and 3sec, depending on spindle type.

RK International says a number of factors highlight the build quality of these machines.

For example, over 200hr of scraping is carried out on each machine to ensure high levels of geometric accuracy, while the X-axis guideways are on different levels to optimise the rigidity of the machine’s column/head assembly.

Meanwhile, thermal compensation is controlled automatically through the CNC system, which can be either the Siemens 840D SL or Fanuc 30i/31i B5.