The software specialist CoreTechnologie (CT) — with operations in Germany, France, the USA, Japan and Great Britain — has developed the 4D_Additive Manufacturing Software suite.

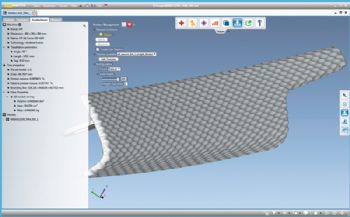

A particular highlight of the new software is the texture module, which gives developers and industrial designers access to over 5,000 different surface structures.

CT says: “The combination of the software with precise B-Rep kernel and the high-resolution HP Jet-Fusion process allows the additive production of very fine and completely new surfaces, which will find application in the future for individualised decorative trim in vehicles and plastic design products.

“Flexible customisation and new component designs are an important innovation advantage in a highly competitive buyer market.

"For users, 4D_Additive makes it easy to define textures on the CAD model, simply choosing the desired B-Rep areas and a matching texture from the database.

"Thereafter, the fineness and position of the structure can be visually adjusted on the component. A rendered, almost photorealistic representation of the model accelerates the work and allows an immediate assessment of the print result. The software automatically ensures distortion-free projection of the grain over surface boundaries.

"The graphical representation allows the assessment of the designed geometry and fuels the creative process in the design of new parts.”

In addition to the texture module, the 4D_Additive Software Suite features ‘healing and clean-up capabilities’, automated part alignment, ‘intelligent’ nesting capabilities with multi-processor calculation, an analysis tool for optimal part design, part optimisation, and shell geometry and a part-finder as a search engine for 3-D printing parts for the fully automatic classification of components on the basis of the geometric properties of the CAD models.

Further information can be found at the Web site (

www.coretechnologie.com/products/4d-additive).