Wire electrical discharge machining (WEDM)is a mature technology, but Coventry-based GF Machining Solutions Ltd (

www.gfms.com/uk) is continuing to ‘challenge convention’ with its new horizontal CUT AM 500.

Said to combine speed with accuracy, this machine has been designed specifically for the metal additive-manufacturing (AM) market — and to simplify the way that additive-manufactured parts are separated from the build plate.

Martin Spencer, GF Machining Solutions UK’s managing director, said: “This machine makes a significant and valuable contribution to the AM process, providing a more-accurate and reliable solution than using standard EDM machines or bandsaws for these operations.

“Moreover, the CUT AM 500 complements — and can be integrated with — GF Machining Solutions’ and 3D Systems’ scalable workflow-optimised DMP Factory 500, DMP Flex 350 and DMP Factory 350 3-D metal printing machines.

“The CUT AM 500 addresses a number of quality issues encountered by manufacturers who use a bandsaw to separate the workpiece from the build plate.

“These issues include geometrical inaccuracy, loss of workpiece material (kerf) and damage to the part.

"The CUT AM 500 maintains the integrity of the part by avoiding part contamination and damage — advantages that are particularly crucial in risk-averse sectors such as aerospace and medical.”

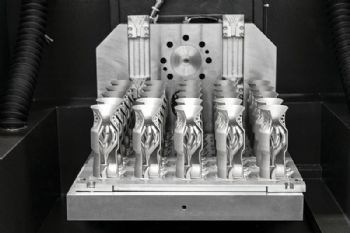

The CUT AM 500, which accommodates parts up to 510 x 510 x 510mm (including the base plate) and weighing up to 500kg, uses 0.2mm-diameter wire to separate additively manufactured parts from the build platform — at a maximum cutting speed of 300mm

2/min,to an accuracy of ±0.1mm and with a surface roughness of less than 6μm.

This equipment brings together horizontal wire orientation, an integrated basket to catch separated parts, and a rotary axis to create a robust process that supports the part, improves part handling, prevents damage to the part, and can be fully automated for increased productivity.

The combination of the CUT AM 500’s generator and ‘fast wire technology’ ensures that the process is quick — at least three-times faster than when using a standard EDM machine — and that the running costs are kept low.