Laser machining, a next-generation technology, is now available through Wellesbourne-based

Engineering Technology Group (ETG), a technical partner of the

Winbro Technologies Group.

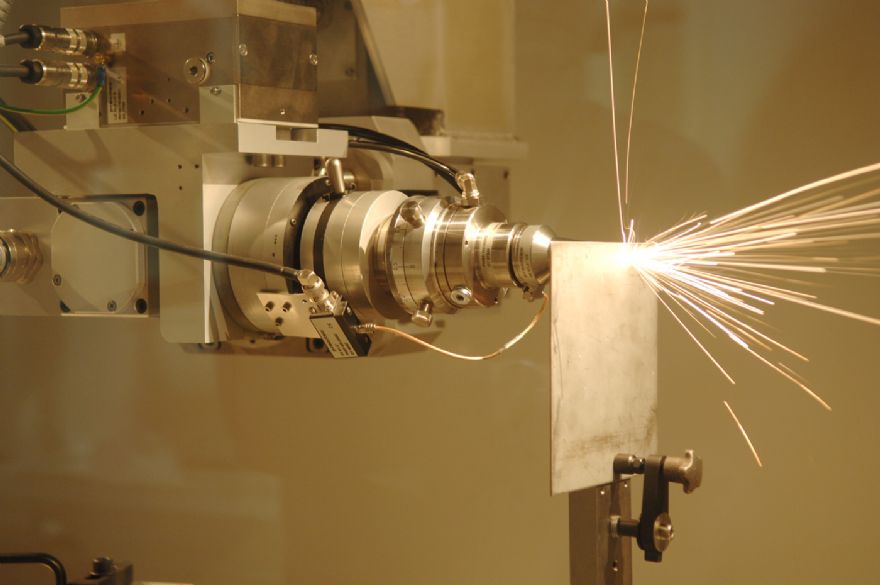

The Winbro Delta laser machining system can be used on a variety of applications including percussion drilling, drilling on the fly, five-axis high-speed cutting, welding, 2-D and 3-D shaped hole machining via ablation, ceramic coating removal via ablation, as well as aerospace cladding for repair or overhaul.

The flexibility of the laser system makes it possible to combine these processes in a single machine platform by using dual laser sources which reduces the user’s machine inventory and footprint requirements.

All this is possible through a machine tool that has a robust design construction and multi-axis flexibility, a large working envelope and a choice of laser types.

Within the compact footprint of the Winbro Delta laser machine is a spacious work area that offers an X, Y and Z axis travels of 1,500 x 750 x 1,000mm for the continuous C-axis rotary table and a B-axis of +/-140deg. It is capable of a linear and rotary accuracy of 0.015mm and 15 arc/sec respectively. Additionally, the repeatability of the machine is first-class with a linear and rotary repeatability of 0.010mm and 10 arc/sec respectively.

Within this spacious, flexible and precise platform is a raft of technology advancements such as component scanning and mapping, focus control, a patented six-point probing system, breakthrough detection, crash protection, tool-tip interpolation, a quick-change nozzle system, a selection of nozzle assemblies.

The Delta can be integrated with different types of Yag and CO

2 lasers and in particular a range of highly productive fibre lasers, the choice of which is dependant upon application. The machine is controlled by a Heidenhain iTNC640 CNC and PC, and is programmed using the latest Winbro advanced post-processor (TCPro and TCPost) taking data from the users' CAD output to define the component geometry and provide an intelligent interface for component process development.