The 180-10-A Series of single flute routers from

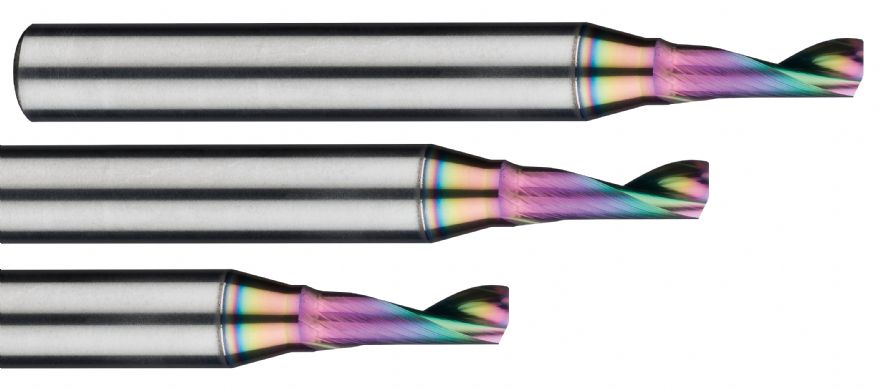

Industrial Tooling Corporation (ITC) has been extended with the addition of a ‘Vitreo’ coated router for machining aluminium composite material (ACM) and an ‘Iridis’ coated variant for the machining of aluminium.

The high-quality solid carbide routers, which have ben developed and manufactured at the company’s Tamworth base, have long been popular with the sign-making sector with performance that is the benchmark of the industry. As the industry has evolved, so has the materials being processed and therefore the cutting tools for machining the ever-increasing range of materials.

The 180-10-A Series single flute router with the new Vitreo coating is a solid carbide tool with an upward spiral geometry that incorporates a 30deg helix with a reinforced 6mm shank. Manufactured from ultra wear-resistant micro-grain carbide, the new Vitreo coated range is perfect for reducing the number of collet changes and prolonging to life when machining aluminium composite material (ACM).

Furthermore, the combination of an efficient tool geometry with an extremely hard-wearing coating provides high-quality surface finishes that significantly reduce secondary finishing operations.

The 180-10-A Series is available with 2, 3 and 4mm diameters with a 6mm reinforced shank, an overall length of 50mm and the length of cut that is 7mm on the 2mm diameter tool, 10mm on the 3 and 4mm variants. This geometry further enhances the rigidity and strength of the tool, which subsequently results in fewer collet changes.

For machining aluminium, the new 180-10-A Series is also available with the same tool dimensions and geometry but with an Iridis coating. Unlike the Vitreo coating for ACM, the Iridis coating has been specifically developed for the machining of aluminium at high speeds.

The coating technology guarantees exceptional surface finishes that is complemented by the tool geometry which minimises burrs.