Zeiss Industrial Quality Solutions

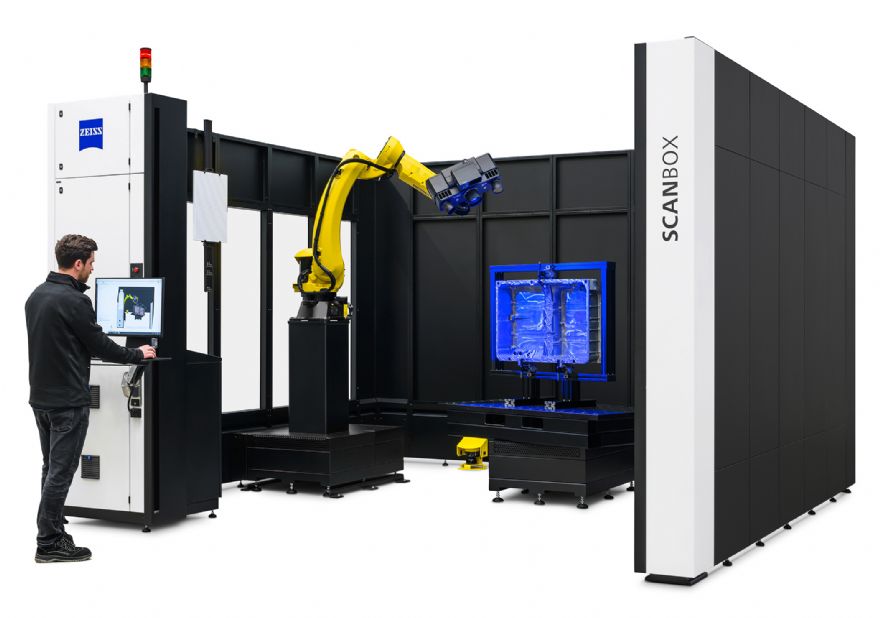

Zeiss Industrial Quality Solutions has expanded its range of optical 3-D measuring machines with the introduction of the new Zeiss ScanBox Series 5, which builds on the proven automated Zeiss ScanBox systems with additions such as an optimised robot module and a rotary table with a load capacity of up to 2 tonnes. Also included are an ATOS 5 high-speed 3-D sensor that allows complex parts made of different materials — such as plastic, metal or cast iron — to be ‘digitised and inspected’ in the shortest possible time.

With each measurement, the optical sensor captures the entire surface geometry as well as hole patterns and other characteristics of the part. Moreover, Zeiss ScanBox Series 5 provides full-field 3-D measurement coordinates that can be compared against the CAD model and used for reporting.

Deviations in terms of geometric dimensioning and tolerancing (GDT), as well as trimming and hole positions, are visualised in the GOM Inspect Pro software. Programming and controlling the measuring sequences is done via the virtual measuring room (VMR).

ZEISS ScanBox Series 5 was designed and developed mainly for series measurements in production environments. The ‘robust housing and sensor design’ and the compensation for temperature fluctuations enable smooth operation even in harsh environments — such as foundries or the forging industry. Comprising three variants, the new model series offers a high degree of flexibility to suit different application requirements: Zeiss ScanBox 5110 can inspect smaller parts (up to 1m, such as turbine blades); the 5120 model allows for automated quality control of larger parts (up to 2m, such as ‘interior components’); while the Zeiss ScanBox 5130 can be used for measuring ‘hang-on parts or tools’ with a maximum diameter of 3m.

Modular principleBased on a modular principle, the new Zeiss ScanBox Series 5 models can be configured in different ways. Because the base components, control tower, rotatry table and robot module are identical in construction, the layout of the measuring room can be easily expanded at any time. In addition, the entrance of the 5110 and 5120 models can be equipped with either a door or a safety light curtain.

For optimum access, especially for larger test components, the 5130 model is always supplied with a safety light curtain. Furthermore, the Zeiss ScanBox 5120 and 5130 models can be specified with a pallet-loading system.

ScanBox systems feature hardware and software that is fully integrated. Moreover, the GOM Inspect Pro control and measurement planning software, in combination with the virtual measuring room (VMR), enables fully automated measurement sequences; and after importing the CAD data and the corresponding measurement plan, the software computes the required sensor positions and robot paths.

Furthermore, thanks to a Smart Teach function, measurement positions in the VMR are automatically updated when the CAD or individual elements change. After the inspection has been completed, any deviations are identified in GOM Inspect Pro and can be displayed in a report with images, tables, diagrams, text and graphics.