The Italian company

Salvagnini — which for more than 60 years has been designing, producing and selling flexible systems for sheet metal processing, has 25 branches, five plants, more than 8,000 installations in 85 countries, and a UK subsidiary in Ross-on-Wye — has chosen

EuroBLECH 2024 for the world premiere of its Generation 4 products (Hall 11, Stand D94).

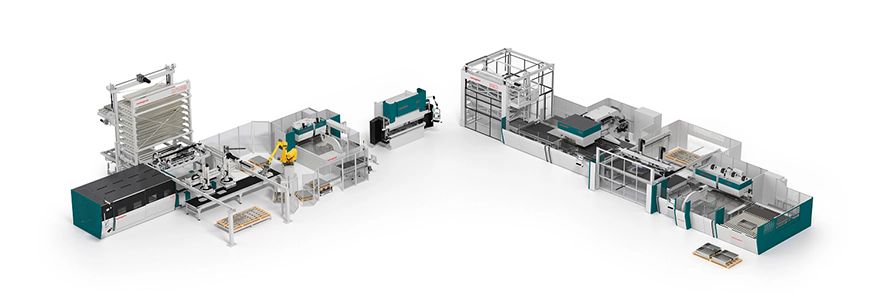

Salvagnini will be showing two highly automated factory solutions that can ‘operate both in stand-alone and collaborative modes, enhance ease of use and repeatability in operations, eliminate low-value tasks, reduce lead times, and optimise production flows for increasingly lower unit costs and greater competitiveness’.

The first solution is the Flexible Smart Line (FSL) S4+P4, which integrates machines, people, and big data into ‘a single ecosystem’ that analyses and interprets data to implement intelligent production flows that reduce waste, scrap, and energy consumption. An ‘MD’ single-sheet warehouse feeds the S4 punching-shearing machine, while the ‘MC’ cartesian manipulator can unload and stack parts, feed the P4 panel bender, and balance the production pace. Furthermore, the company’s FLOW software autonomously manages the machines, optimising results according to the selected production mode.

FSL introduces the new S4.G4 punching-shearing machine, which offers reduced energy consumption, application versatility, structural simplicity, and features ‘advanced hybrid actuators’ that reduce average consumption by up to 20% — and eliminate maintenance. MC is the automatic sorting solution that allows for stacking punched parts with various strategies, while Nexus software automatically generates sorting programs via the integrated 3-D simulator.

The second solution is a Flexible Smart Job (FSJ) Shop. A combination of three different stand-alone systems that can collaborate when needed to manage convergent productions, the connection between the various systems is ensured by software, as well as by transfer units and AMRs (autonomous mobile robots). The Flexible Smart Job Shop can also integrate intermediate warehouses or additional workstations upstream and downstream. This FSJ comprises: the new L3.G4 laser (in a fully automated configuration with LTWS warehouse), MCU sorting device, and conveyor transfer unit; P-Robot, an application that combines a P2-2120.G4 panel bender with a six-axis anthropomorphic robot; and a B3 press brake equipped with ATA devices for the set up of upper and lower bending tools.

The L3.G4 features a gantry solution that ensures maximum accessibility to the work area, as well as increased robustness and precision in processing. P-Robot introduces the RVS artificial vision system, which recognises incoming parts on the conveyor and manages their loading without operator intervention or centering, regardless of their positioning.

Salvagnini will also show its new P2-1620 panel bender, which joins its four existing models and completes the company’s range of compact panel benders.