Oxfordshire-based

Plasmatreat UK will be demonstrating how plasma technology works for surface treatment and how the technology can reduce ‘the carbon footprint’ at

Advanced Engineering 2024 later this week (Stand Q180). The show is taking place at the NEC, Birmingham on 30 and 31 October.

With a facility in Wantage, Oxfordshire, the subsidiary of German company Plasmatreat GmbH, will be highlighting its range of plasma systems and equipment, and says these will be of interest to a range of industrial sectors, including automotive, battery production, lightweighting, and aerospace.

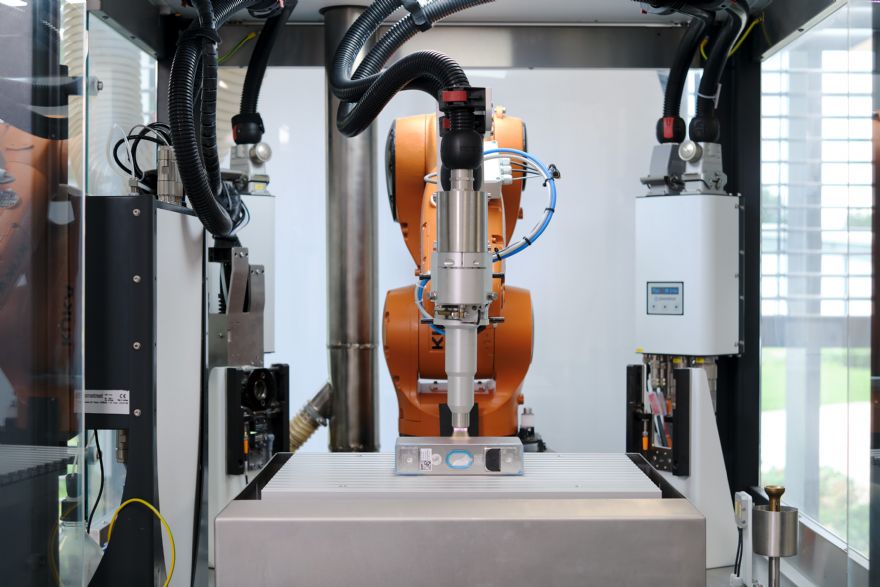

Plasmatreat develops and manufactures the Openair-Plasma and PlasmaPlus systems for the surface treatment of a wide range of both materials and applications. These treatments not only improve the surface properties of materials such as plastics or metals but also contribute to increased efficiency and sustainability in manufacturing processes. Surface pre-treatment includes the processes of cleaning, activation and coating.

Visitors to

Advanced Engineering will learn about Openair-Plasma pre-treatment solutions specifically tailored to the needs of the automotive and battery industries. These include the use of plasma activation and cleaning to improve the adhesion of liquid or solid seals, adhesives, and paints or varnishes, as well as plasma coating for ‘reliable and environment-friendly corrosion protection of battery or control housings’.

Latest developments in plasma technologyAndrew Nixon, Plasmatreat UK’s sales manager, said: “

Advanced Engineering’s focus on automotive, aerospace, and lightweighting is a perfect match for the industries in which our technology is used. This event gives us the opportunity to highlight our latest developments in plasma technology and discuss future trends and challenges with industry peers.

“Our plasma technology can be reliably and automatically used in the e-mobility segment to clean battery cells prior to filming or painting for insulation, to activate the film/varnish prior to cell-to-cell bonding, or for cylindrical cells prior to wire bonding. Furthermore, the AntiCorr plasma coating for durable, selective, and dry protection against infiltration corrosion is used by manufacturers of battery or control housings. In lightweight construction, the technology scores by saving weight through reliable, structural bonding of various plastic-plastic or plastic-glass joints.”

The Plasmatreat Group has technology centres in Germany, the USA, Canada, China, and Japan; and with its worldwide sales and service network, the company is represented in more than 30 countries by subsidiaries and sales partners.