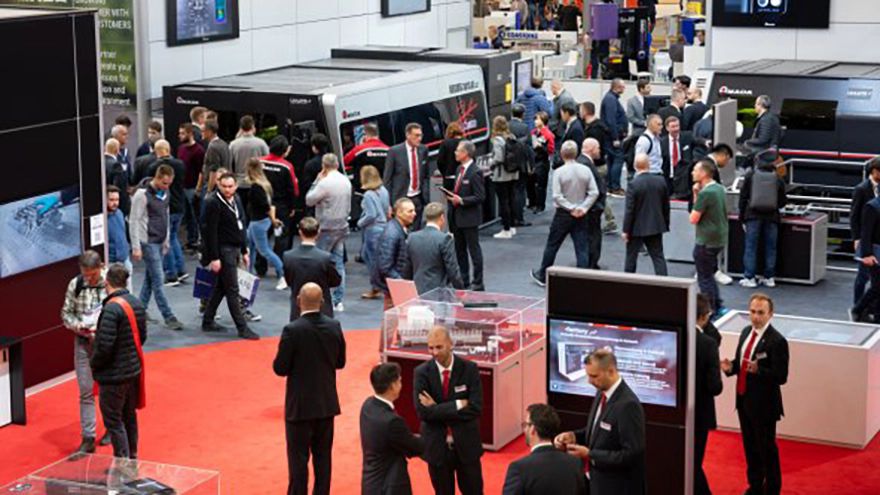

Amidst ongoing global challenges, the sheet metal working industry showcased its dedication to progress and growth at the 27th International Sheet Metal Working Technology Exhibition,

EuroBLECH 2024 held at the end of October n Hanover. With 38,946 trade visitors from 114 countries and 1,317 exhibitors on 160,000m

2 gross space, the event re-affirmed its role as the world’s leading platform for innovation and business in this sector.

A sense of cautious optimism dominated the halls, with many exhibitors securing substantial orders.

Despite the slowing global economy, there was widespread agreement that key markets will eventually bounce back and grow, together with a clear commitment to driving the necessary transformational change. Determined to focus on new opportunities, the industry has been intensifying its push for innovation. The proactive stance on technological progress was matched with a notable willingness from buyers to consider new investment.

The four-day event delivered on visitor quality, with the majority of visitors classified as key decision makers. The number of unique visitors increased by 3%, with a strong presence from Germany which has recently gained in market importance for certain technology sectors. Besides Germany, the top visitor countries in 2024 were the Netherlands, Italy, Poland, Sweden, Turkey, Austria, Spain, Belgium, Denmark, and Switzerland. There was also significant growth in visitor numbers from Asia (Japan, Taiwan, India) and South America (notably Argentina), pointing towards promising new markets for the sheet metal working industry.

Groundbreaking innovationsEuroBLECH’s impressive nine exhibition halls hosted a wealth of product launches and groundbreaking innovations, sending a bold signal for technological progress and growth opportunities within the sector. Throughout all 15 technology areas, machine makers displayed a clear commitment to enhancing production efficiency through technical innovation.

Key technologies included, but were not limited to: a new artificial intelligence (AI) vision system for fully automated sorting of laser-cut parts; remote machine diagnostics and monitoring for fast troubleshooting and servicing; highly automated factory systems that integrate people, machines, and data into smart production flows; folding machines with fully automatic tool changer; simplified and robust laser-cutting machines particularly suited for new users; modular or compact bending cells for smaller production environments; a substantial 20kW high-speed and high-precision fibre laser cutting machine for extra demanding applications; AI-driven robotic software for complex and adaptive applications; and many other advancements.

Of the many innovation leaders on the exhibition stands, 76 companies were shortlisted for the prestigious

EuroBLECH 2024 Award, organised in partnership with

blechnet and

MM MaschinenMarkt.

The six winners, chosen by public vote, were recognised for their commitment to advancing technical excellence in: Stamping and Forming — Amada, for its EGB-1303ARse fully automatic bending robot cell; Cutting Technology — Trumpf, for its bevel cutting on 2-D laser cutting machines; Joining Technology — Weil Technology, for its LWC-RT4-BPP laser welding system; Surface Technology — Q-Fin, for its Q-Fin F250 small parts finishing machine; Automation and Handling — Reis Robotics, for its ROBOTstar VII robot controller; and Sustainability — Bosch Rexroth, for its energy-efficient, servo-hydraulic drive solution for deep-drawing presses.

The runner-ups were: Airco, Beneva, Bystronic, CNC Europe/Lasermach, EMC, Engmar, EPCM Expert, Hans Weber Maschinenfabrik, MicroStep Europa, Schuler, and Wilson Tool. Visitors were invited to explore the new ‘Award Trails’, featuring all 76 shortlisted companies and their innovations.

Meanwhile, two dedicated presentation areas in Halls 26 and 27 hosted live talks by prominent industry figures, covering key developments in automation and digitalisation. A special panel discussion focused specifically on solutions for small and medium-size businesses. On the show floor, the new ‘Guided Tours’ launched with success, offering visitors new opportunities to efficiently engage with interesting productivity trends and suppliers.

EuroBLECH 2024

EuroBLECH 2024 also reinforced its commitment to championing young talent and fresh approaches within the industry and one in five exhibitors were new to the show, adding valuable fresh input to the event. This included a group of promising start-ups in the ‘Young Innovators’ pavilion in Hall 15 which highlighted young businesses and innovations from Germany. On Friday’s

Careers Day,

EuroBLECH welcomed students and apprentices who benefitted from free admission and the unique opportunity to engage with groundbreaking technologies and world-class suppliers.

The event ended on a high note after four productive days of fostering connections across the sheet metal supply chain and unlocking new potential for industry players and the high turnout of visitors added to a sense of optimism and achievement among exhibitors.

Evelyn Warwick, event director of

EuroBLECH, on behalf of RX, said: “

EuroBLECH 2024 has proven to be vital for the sheet metal working community, which has shown remarkable resilience and innovation amid economic challenges. This year’s event marked a strategic milestone for many companies as it delivered — once again — an impressive showcase of technological advancements in a promising business environment. We thank all our participants for making

EuroBLECH such a vibrant platform for exchange and growth — their enthusiasm and active engagement in meaningful conversations, ideas, and business ventures is what drives our industry forward.”

The industry remains strongly committed to

EuroBLECH as its primary platform for innovation, business, and growth. Following this year’s success, many exhibitors have already confirmed their participation for the next edition.

EuroBLECH 2026 is set to take place from 20-23 October 2026 in Hanover once again.