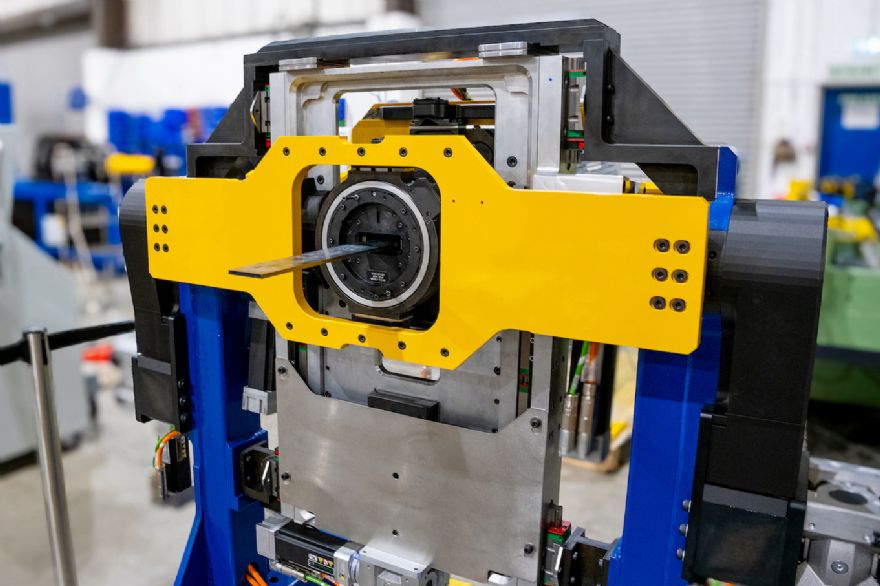

A newly launched flat bar forming machine from Scarborough-based

Unison Ltd, the inventor of ultra-precise, all-electric tube manipulation, is redefining the way stairlift railings, complex fabrications, street furniture, architectural fixtures and other applications that use flat bar materials are produced.

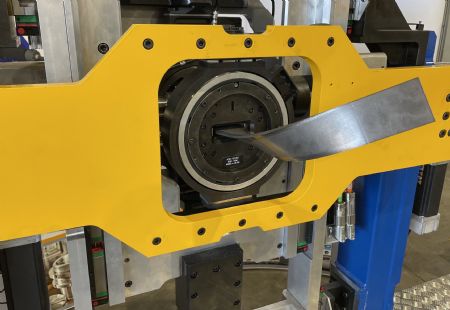

The Unison FLEX flat bar former is designed for the seamless production of flat bar, toothed and pocketed flat bar profiles as well as tubular shapes. It can precision-form the most complex of flat bar designs, including freeform and sculptured shapes in minutes. Additionally, when teamed with Unison’s advanced Opt2Sim Suite of tube simulation software, design for manufacturing production strategies become straightforward and easy.

Alan Pickering, Unison Ltd’s joint managing director, said: “Typically, the flat bar shapes that are used in stairlifts, architecture and other applications are manually fabricated – a process that is particularly labour-intensive for all but the simplest of straight rail installations. Our new FLEX model, however, changes all that. In effect, we have created an all-electric machine and software package that can take a CAD model of a continuously changing 3D shape with a reference surface, then decode it so the shape can be faithfully recreated by continuous 3-D roll-forming.”

Unison’s purpose-developed software allows flat bar shapes to be calibrated for bend and twist, enabling the production of right-first-time parts within the typical constraints of metal tolerance and behaviour. The 3D file import system contained in Unison’s Opt2Sim tube simulation software suite, enables users to drag and drop STEP files into the software application and access bending data instantly. Alternatively, parts can be drawn by entering XYZ coordinates or YBC data then viewed in 3-D.

For the precise creation of the calibration files necessary for accurately reproducing - and verifying - the various bends and twists of even the most complex of flat bar components, Unison’s advanced Opt2Sim Scan portable tube and bar geometry scanning solution can also be specified with the new FLEX Flat Bar Former.

Considerable scan pointsPossibly the most advanced hand-held tube measurement system on the market, Opt2Sim Scan incorporates a Creaform3D hand-held scanner for precise, portable 3-D scanning of the component the user wishes to replicate or measure. With considerable scan points, the system’s constant reference geometry ensures accurate results without the need of a skilled operator. Scanned dimensions are easily compared to master file data, with corrections sent directly to the bar bending machine.

Mr Pickering added: “We really have done everything possible to make creating complex flat bar metal shapes incredibly straightforward, even to the degree of allowing for real-world material dimensions and calibrating around such characteristics. Our new Unison FLEX Flat Bar Former really is bringing new levels of control, precision and time-saving to the manipulation of flat bar materials and is already generating considerable interest and orders from stairlift manufacturers in particular.”

Unison Ltd is the UK’s leading manufacturer of tube and pipe bending machines and continually innovates the tube and pipe bending marketplace. The company manufactured the world’s first all-electric tube bender in 1994, followed by the world’s first all-electric multi-stack tube bender, then the world’s largest all-electric tube bender for the shipbuilding industry.

Available in single-stack, multi-stack and right/left varieties, Unison machines are delivered to more than 20 countries around the world. Unison’s tube-bending software is recognised as the most user-friendly control system for tube bending machines. The software is written and supported by Unison, ensuring complete control of its evolution, with no need for third party support.