Now available from

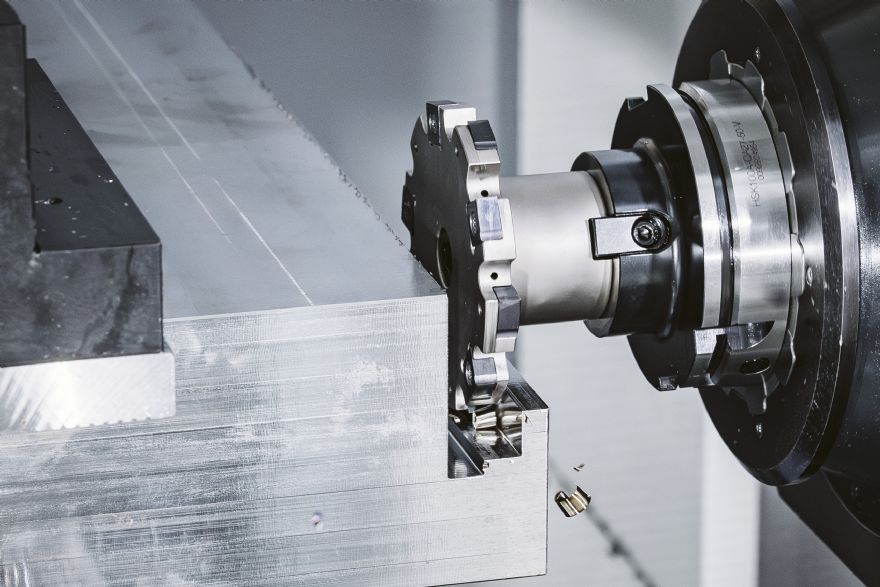

Ceratizit for cutting grooves in steel, stainless steel, cast materials or aluminium are the soft-cutting side-milling cutters in the company’s MaxiMill-Slot-SNHX system which, thanks to its choice of carriers and indexable inserts, covers cutting widths from 6 to 16mm and diameters from 50 to 200mm. Ceratizit says: “MaxiMill-Slot-SNHX cutters feature trouble-free contours on the face side and sufficient axial freedom of movement to ensure smooth machining, even in hard-to-reach areas, while the precision-ground indexable inserts provide a flat groove base and perfect surfaces from the very first cut.

“The MaxiMill-Slot-SNHX is available in three carrier variants. The slip-on milling cutters offer diameter ranges from 80 to 200mm, each with an internal coolant supply and cutting widths of 6, 8, 10, 12, 14 and 16mm. The screw-in milling cutters also provide an internal coolant supply, but with diameters of 50, 63 and 80mm and cutting widths of 6 and 8mm. Third are the cylindrical shank cutters. Available in diameters of 50, 63, 80 and 100mm and cutting widths of 6 and 8mm, these also offer an internal coolant supply.”

Precision groundThe indexable inserts in the MaxiMill-Slot-SNHX are precision ground and suitable for P, M and K applications. They will initially be available with a corner radius of 0.8mm and a 3deg axial mounting position in the milling cutter to ensure ‘good clearance and even makes rear-side machining possible’; and to ensure errors cannot occur when fitting the indexable inserts, the carriers are labelled accordingly on the insert seats — and there are clear markings for right and left indexable inserts.

Ceratizit says MaxiMill-Slot-SNHX tools compare favourably with competitors’ products. “Tests in the back machining of ductile cast iron saw a competitor cutter machine 200 parts with a carrier tool having a diameter of 160mm, six effective cutting edges, an in-feed depth of 3mm, and an insert width of 42mm. Our solution, which uses five active teeth, increased tool life to 600 parts. In addition, machinists benefit from better handling due to the large insert clamping screw and minimised set-up effort with fewer indexable inserts.”