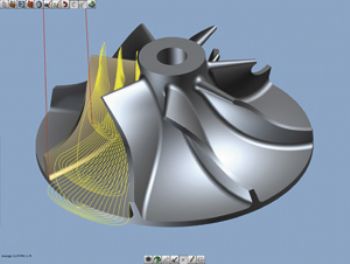

@EMO_HANNOVER The HyperMill 2013 CAM package from Open Mind Technologies (Hall 25 Stand K16 –

www.openmind-tech.com) offers a number of new features, extensive functional upgrades and greater ease of use.

The most significant advance comes with the new ‘HyperCAD-S’ CAD core, which is optimally matched to the HyperMill CAM solution. There is also a multitude of enhancements throughout many of the package’s established strategies.

For example, the MillTurn feature — of increasing importance, given the growing popularity of multi-functional mill/turn centres — now incorporates full machine simulation and collision checking of rotational chucks and clamps. It also includes a hard-machining feature for Inconel, titanium and other difficult-to-process materials that demand variable in-feeds and automatic ramping.

Support of the steady rest and tailstock, with automatic and manual positioning and individual cutting parameters for contours, have also been included in the MillTurn package.

With regard to HyperMill’s 2.5-D and Macro element, Open Mind has created a new minimal-distance parameter for holes, plus a generic feature for ‘pockets’ that is equivalent to ‘generic hole’. Further additions include a 2-D contouring feature that enhances compen-sation and tolerance checking.

The 3-D strategies for more-complex machining have also been improved in HyperMill 2013, with enhancements including a 3-D arbitrary stock roughing cycle for the better checking of conical tools. This has also been extended to HyperMaxx, providing multiple allowances for feed-rate control, entry and plunging into pockets.