@EMO_HANNOVER #ukmfg The latest innovation from Taunton-based wet-blasting specialist Vapormatt Group (Hall 3 Stand C34 –

www.vapormatt.com) is a programmable gun crown for use with its Tiger and Tiger+ systems.

This increases the number of ‘recipes’ that can be programmed for the edge preparation of tooling, enabling multiple tool sets to be honed and polished using the same in-line system without the need to change gun heads for different blasting angles.

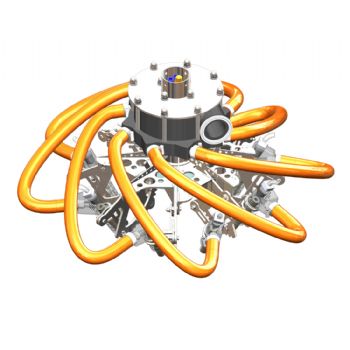

The new programmable gun crown features eight blast nozzles, each fully adjustable to offer a range of processing angles. With this single gun crown, programmed via the Human Machine Interface (HMI), users can hone and finish

a range of different tools, each with different K factors and radii, without having to change gun angles for different recipes.

The stainless-steel crown assembly, which is designed for reliability and repeatability, features a robust worm gear and cam mechanism that are controlled by a servo motor. This ensures that the nozzles move in unison to deliver a blast stream that always achieves the desired angle.

The HMI unit allows the servo motor to position the guns at any desired angle between 50 and 90deg, providing a range of different edge-honing geometries for cutting inserts.