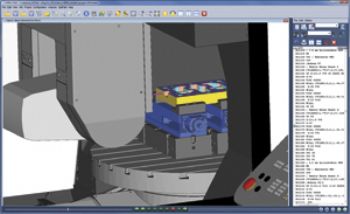

@EMO_HANNOVER #ukmfg New features introduced to Vericut 7.3 CNC machine simulation, verification and optimisation software include enhancements that significantly improve performance and further simplify the process of simulating a CNC machine. Performance is now five to 10-times faster when the NC program moves the simulated machine into potential collision conditions, and constant gouge check simulation with large design models is now two- to five-times faster. In fact, more than 400 customer-driven enhancements and software change requests have been completed since version 7.2.

John Reed — managing director of CGTech Ltd, Hove (Hall 25 Stand J30 –

www.cgtech.com) — says changes to the user interface further improve work-flow and are a direct result of continuous product improvement based on customer feedback.

By enabling users to eliminate the process of manually proving out NC programs, Vericut reduces scrap loss and re-work. It also optimises NC programs and simulates all types of CNC machine tools, including those from leading manufacturers such as DMG-Mori Seiki, Mazak, Makino, Matsuura, Hermle, Starrag, Heller and Chiron.

The software can also be integrated with leading CAM systems such as Dassault Systemes CATIA, Siemens NX, MasterCAM, Delcam PowerMill, Vero EdgeCAM, Open Mind HyperMill, DP Esprit and Missler TopSolidCAM.

Furthermore, the Vericut 7.3 user interface features all-new icons, available in multiple sizes and with several user-selectable colour themes — plus there is the option of either displaying or hiding every window and icon.

User-configurable ‘favourites’ further simplify setting up a simulation session (these consist of commonly used folders and files, and each item can be dragged/dropped into a specific project).

To help objects stand out when undertaking machine simulation, an ‘Edge Display’ option analyses models and finds and displays their edges — without affecting the simulation speed.

Moreover, during a simulation, the user can create a list of ‘stop at’ events, such as ‘collisions’, ‘warnings’, ‘tool changes’ and ‘end of each set-up’; these can be managed interactively in the NC program dialog. The user can add, move,remove or temporarily disable the events that pause the simulation.